Discover our approach

STARK Resources is a specialised, privately held engineering group, with a global mining footprint. We focus on fast-tracked design, fabrication and construction of fit-for-purpose minerals processing plants on a fixed price basis (EPC/LSTK). Plants are pre-fabricated, assembled and tested on site at our 5,000 m² facility in Centurion, South Africa. The team specialises in delivering projects in developing countries and Tier-1 jurisdictions.

Our cross-disciplinary team of geologists, mining engineers, and process engineers collaboratively focuses on assessing an orebody, maximising deposit value, all while prioritising risk minimisation. With this tailored approach, we enabled you to unlock the full potential of your orebody within your financial means.

How far along is the development of your asset in the lifecycle of a mineral recovery?

Hover over the graph and click on the segment that best reflects where your asset is in the lifecycle of a mineral recovery. You'll be directed to more information.

Concept

Perform surface exploration and validate geological hypotheses.

Know MoreDiscovery

Identify viable mining deposits with tailored consultation and testing.

Know MoreFeasibility

Confirmed discoveries demand significant capital without generating income yet.

Know MoreDevelopment

Cutting-edge technologies are adopted to establish a streamlined mine.

Know MoreDepletion

Optimal ore recovery and sustainable extraction for the mature mine.

Know MoreFeasibility

Confirmed discoveries demand significant capital without generating income yet.

Let’s reduce the impact of mining by taking a holistic approach and enabling sustainable mining practices, to do as little harm to the world as possible.

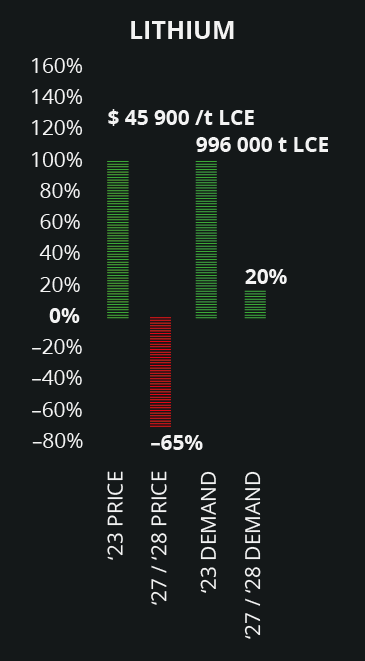

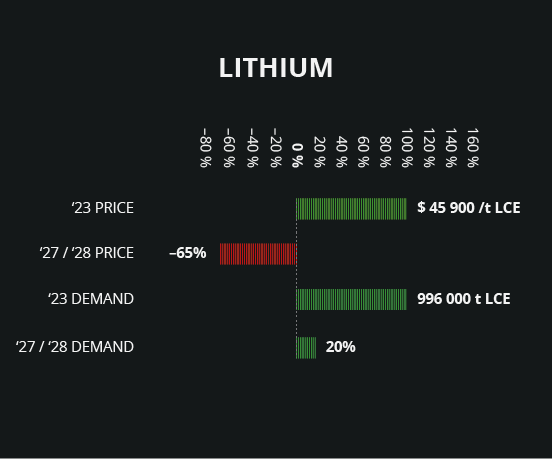

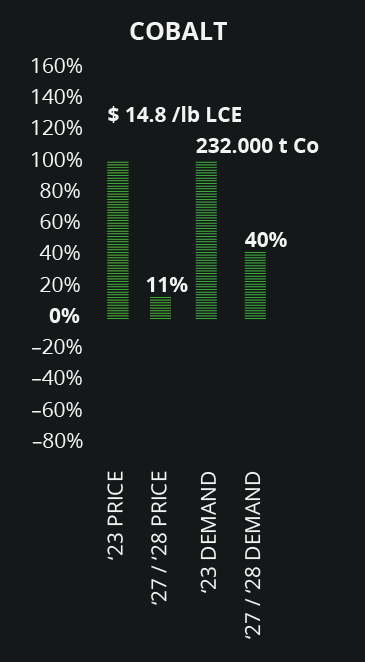

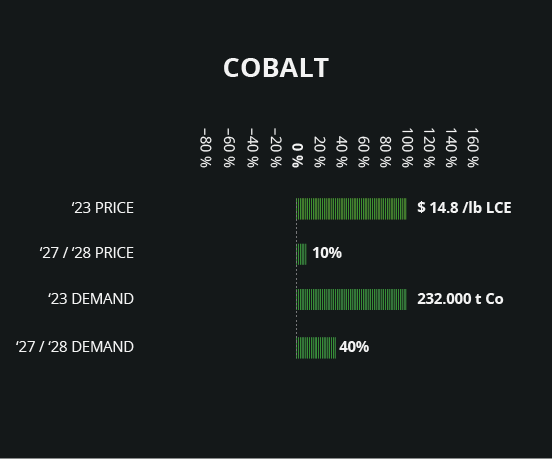

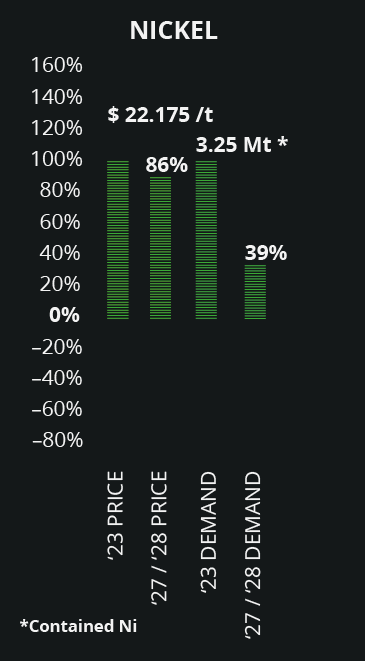

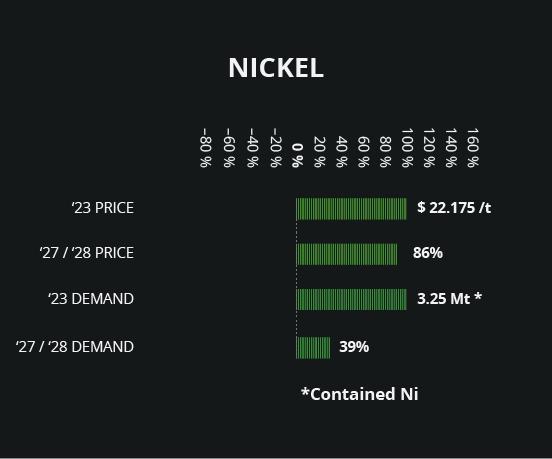

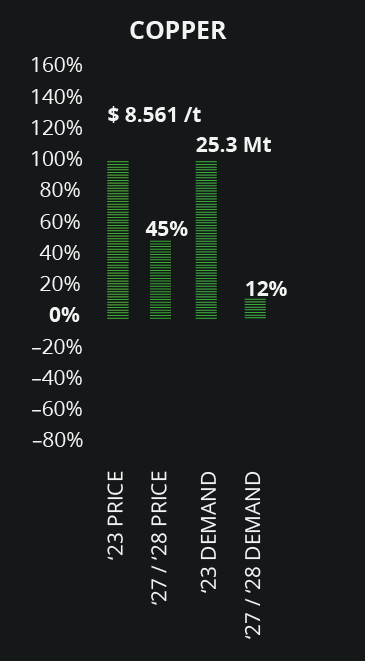

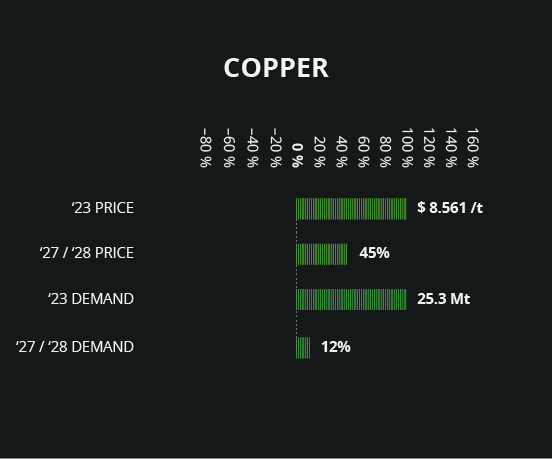

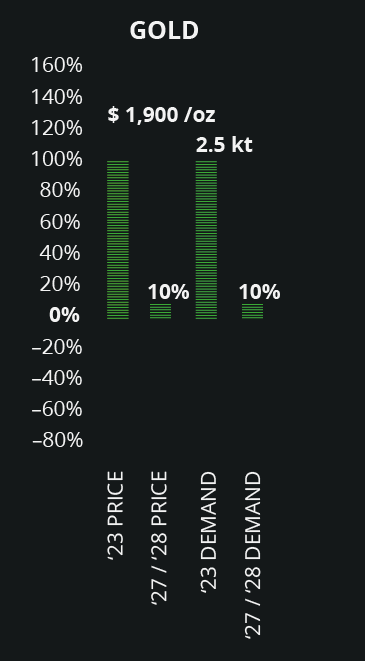

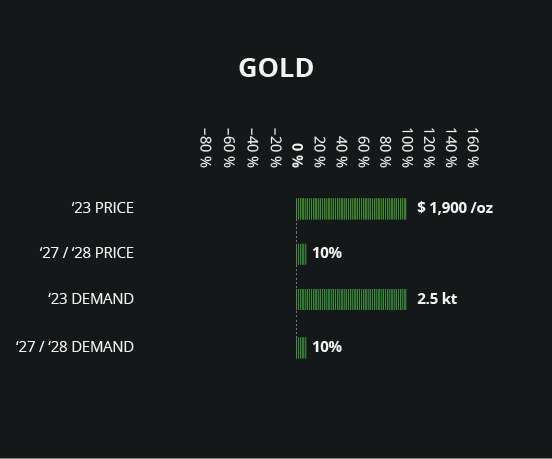

GLOBAL MARKETS FOR CRITICAL METALS

The energy transition is driving demand for a group of critical metals (including lithium, cobalt, nickel and copper) essential for clean energy technologies. The significant production growth in coming years to meet global and national energy transition targets will make efficient mine deployment crucial in ensuring a sustainable supply of these critical resources. CRU Group, with its decades of experience in the mining industry, is closely monitoring the global markets for these critical metals. Below, we provide an overview of the current situation and outlook for each of these markets.

We are your partner of choice through every stage of your asset's lifecycle, from operations at potential Greenfield sites all the way through to optimising operating assets to improve profitability and prolong mine life.

CEO Geoffrey Madderson

Let's chat

Eugene Collins

MINERAL RECOVERY ANALYST

Pr. Eng. / B. Eng. (Chem.)

| Germany | |

| +49 152 358 28748 | |

| eugene@stark-resources.com |

Eleanore Luise Forner

PRINCIPAL - LITHIUM

Pr. Eng. / B. Eng. Hons (Chem.)

| South Africa | |

| +27 82 316 8568 | |

| eleanore@stark-resources.com |

Sonja Schadeck

Techno Economic Engineer - Lithium

M. Sc. BA & Eng. (Mech.)

| Germany | |

| +49 173 188 6604 | |

| sonjas@stark-resources.com |

Check our solutions

Latest Insights –

let's dig deeper!

Insights

August 8, 2023

Interesting Facts About Spodumene to Know

Durban, South Africa — Spodumene belongs to the pyroxene group of minerals and has a monoclinic…

Insights

July 27, 2023

What is a Lithium Battery?

Durban, South Africa — A lithium battery is a rechargeable product that uses lithium ions to…

Insights

July 25, 2023

What You Need to Know About the Lithium…

Durban, South Africa — Today’s lithium price is created from several data points. Like most products,…

Discover more News & Insights!

Locations worldwide

Contact us