STARK Resources is a specialised, privately held engineering group, with a global mining footprint. We focus on fast-tracked design and construction of minerals processing plants on a fixed price basis (EPC/LSTK). We specialise in delivering projects in developing countries and Tier-1 jurisdictions.

This expertise bridges our understanding of in-ground ore deposits with tailored recovery solutions, ensuring a compelling and economically viable proposition across the entire mining value chain, from Greenfield exploration projects to active production mines, including the implementation of the world's first UV laser technology.

STARK is staffed and managed by mining industry pedigree, many of whom have previously enjoyed careers across disciplines such as geology, engineering, mine engineering, mineral processing, metallurgy, construction, and original equipment manufacturing (OEM) at large-scale operators.

Why STARK?

Unlock the full potential of your orebody within your financial means. We offer clients:

Advisory

services

Our advisory journey blends tailored consultation, championed test work scoping, and in-depth studies with the expertise of engineers and geometallurgical specialists. We optimise geology with processing for unparalleled profitability and sustainability.

Advanced orebody

characterisation

We employ state-of-the-art analytical techniques to meticulously analyse your orebody, recommending recovery technology solutions that are custom-tailored to your unique mineral deposits, with objective test work at independent accredited laboratories independent of OEM sorting suppliers.

Mineral processing

plant builds

We specialise in the in-house design, fabrication and construction of mineral processing plants. With a commitment to quality and efficiency, our designs are robust and pre-fabricated before shipping, ensuring seamless assembly on-site as well as the option to reconfigure and redeploy quickly and cost effectively. We require short lead times and deliver reliable solutions that are both fit-for-purpose and built to last.

Seasoned industry

experts

Our team boasts over 20 years of hands-on-expertise, guided and supervised by industry veterans who have extensive careers with major mining operators.

A collaborative

partnership

We engage with you in a long-term partnership, focused on not just implementing but also continuously optimising your cutting-edge technology solutions.

Unbiased turnkey

solutions

As an independent integrator, we incorporate next-generation ore sorting technologies to maximize your mining project's efficiency and profitability.

Our solutions for clients

STARK works with clients across the world to help them realise their vision. While each project is personalised - no two orebodies are the same - it's possible to classify most client needs by their stage along the mining lifecycle:

Our solutions for clients

STARK works with clients across the world to help them realise their vision. While each project is personalised - no two orebodies are the same - it's possible to classify most client needs by their stage along the mining lifecycle:

Advisory

Is this you?

Do you need to conduct an orebody assessment on a project? Are you wanting to match an optimal recovery solution to your deposit? We build plants and optimisation strategies around the geology of the deposit with an approach that is rooted in economic trade-offs.

Our team leverages a comprehensive gap analysis – encompassing geology, geotechnical engineering, mine planning and engineering, metallurgy, metallurgical test work, ore sorting tests, and mineral processing designs. We’ll pinpoint avenues for optimal value generation.

Advisory

Is this you?

Do you need to conduct an orebody assessment on a project? Are you wanting to match an optimal recovery solution to your deposit? We build plants and optimisation strategies around the geology of the deposit with an approach that is rooted in economic trade-offs.

Our team leverages a comprehensive gap analysis – encompassing geology, geotechnical engineering, mine planning and engineering, metallurgy, metallurgical test work, ore sorting tests, and mineral processing designs. We’ll pinpoint avenues for optimal value generation.

Small-scale Greenfield Plants

Is this you?

Are you looking for a fast-start operation, with an outlay of less than US$10 million, and often much less? While these plants are designed to be revenue-generating from day one of handover, the focus is to help improve the understanding of a deposit, which has seen limited analysis, and prove potential profitability to funding houses, offtake partners, or potential Joint Venture partners.

As these plants are relatively simple, they can be built in as little as six months.

Small-scale Greenfield Plants

Is this you?

Are you looking for a fast-start operation, with an outlay of less than US$10 million, and often much less? While these plants are designed to be revenue-generating from day one of handover, the focus is to help improve the understanding of a deposit, which has seen limited analysis, and prove potential profitability to funding houses, offtake partners, or potential Joint Venture partners.

As these plants are relatively simple, they can be built in as little as six months.

Large-scale Greenfield Plants

Is this you?

Have you already conducted significant orebody analysis, and perhaps have a Scoping Study or the initial work on a Pre-Feasibility Study completed? Perhaps you've already secured circa $40 million to build a large-scale modular pilot plant through a funding partner. The primary focus of these plants is to generate revenue, with a quick payback time - with improved understanding of the deposit a secondary consideration.

STARK aims to build these plants in less than a year, though the exact timescale will depend on modules required, alongside the quality of surrounding infrastructure.

Large-scale Greenfield Plants

Is this you?

Have you already conducted significant orebody analysis, and perhaps have a Scoping Study or the initial work on a Pre-Feasibility Study completed? Perhaps you've already secured circa $40 million to build a large-scale modular pilot plant through a funding partner. The primary focus of these plants is to generate revenue, with a quick payback time - with improved understanding of the deposit a secondary consideration.

STARK aims to build these plants in less than a year, though the exact timescale will depend on modules required, alongside the quality of surrounding infrastructure.

Brownfield Optimisation

Is this you?

Are you already operating a profitable plant, perhaps in a Tier-1 jurisdiction such as Australia or Canada? STARK has first-class expertise to optimise your entire operation. We can implement a full diagnostic and install our modular solutions in as little as a few weeks, and with a rapid payback time.

Brownfield Optimisation

Is this you?

Are you already operating a profitable plant, perhaps in a Tier-1 jurisdiction such as Australia or Canada? STARK has first-class expertise to optimise your entire operation. We can implement a full diagnostic and install our modular solutions in as little as a few weeks, and with a rapid payback time.

Our clients and partners say

We're so happy to be working with Stark Resources. We're impressed by their competence, experience, dedication, and their ability to think outside the box and solve problems. Very important for early stage and low-cost oriented companies like ours, operating in challenging environments.

Thomas Häggkvist

CEO Africa Resources

We acquired an updated stand-alone XRT plant and within a very short space of time recovered the 91O ct D-colour Lesotho Legend diamond at Letšeng. This must surely rank as one of the best ROIs that has ever been seen!

Clifford Elphick

Chief Executive Officer

Stark has enhanced and vastly improved our XRT sensor-based sorting and tracer testing for primary diamond recovery with bench scale test work, field testing and the full scale implementation of automatic, remote RFID tracer systems. This innovative approach provides further process assurance in real time.

John Armstrong

Vice President Technical Services

Contact us today!

Whether you fit neatly into one of these categories, or perhaps are somewhere in the middle, you can contact Group Commercial Directory, Dian Heinrich Page, he'll be happy to assist.

Our 2030 Vision

We have a bold vision of how the world of mineral recovery can look by 2030.

Smart technology and digital solutions are used to explore and liberate opportunities.

We're pursuing a perfectly balanced processing eco-system that leads to high-resource recovery with minimal impact.

Advanced technologies, like ore sorting, are creating synergies with traditional methods.

Trucks use carbon neutral energy. Chemicals aren't needed.

![]()

Plants are fuelled and powered by self-generated solar and wind energy.

The mining space is transformed into a natural habitat once resources are recovered.

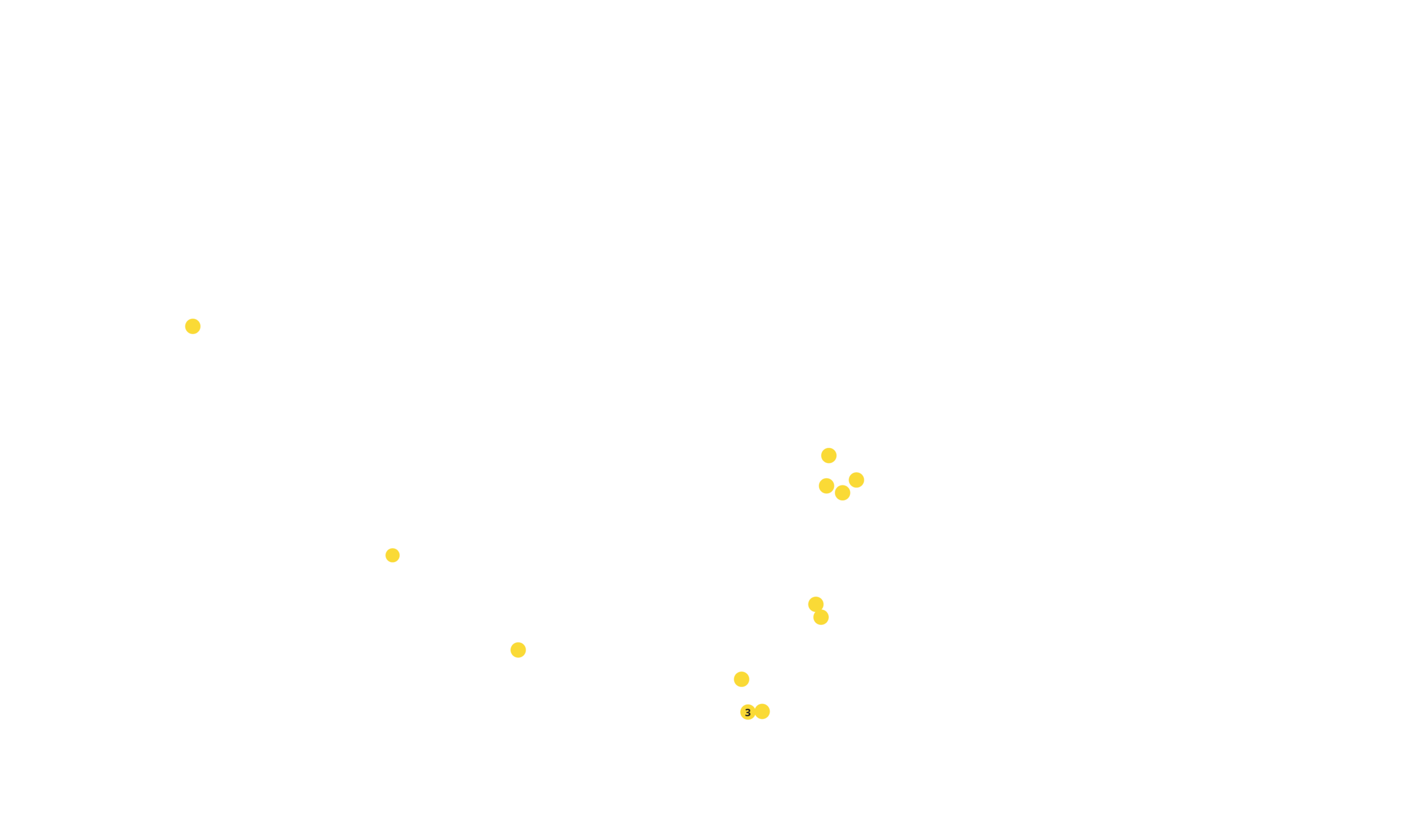

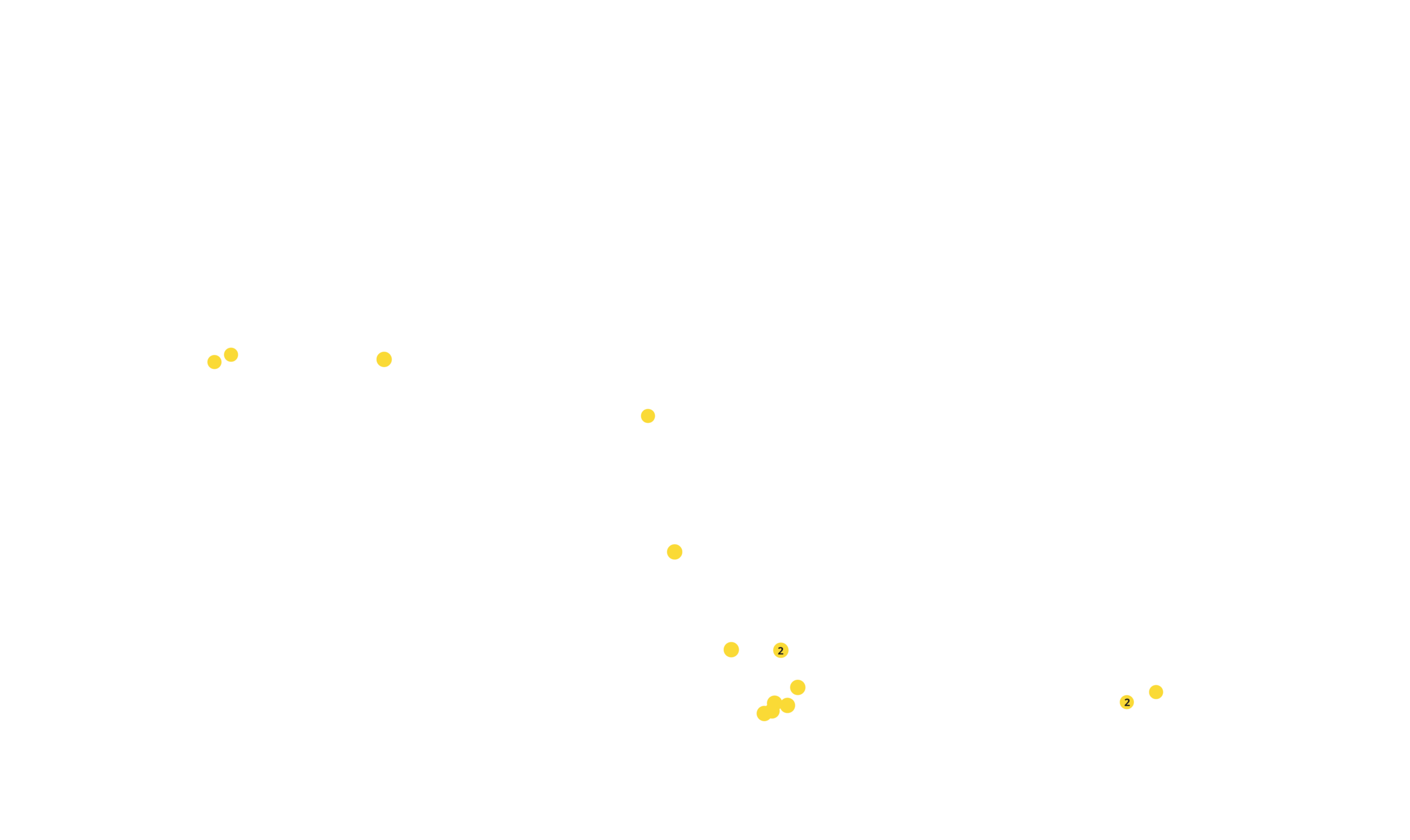

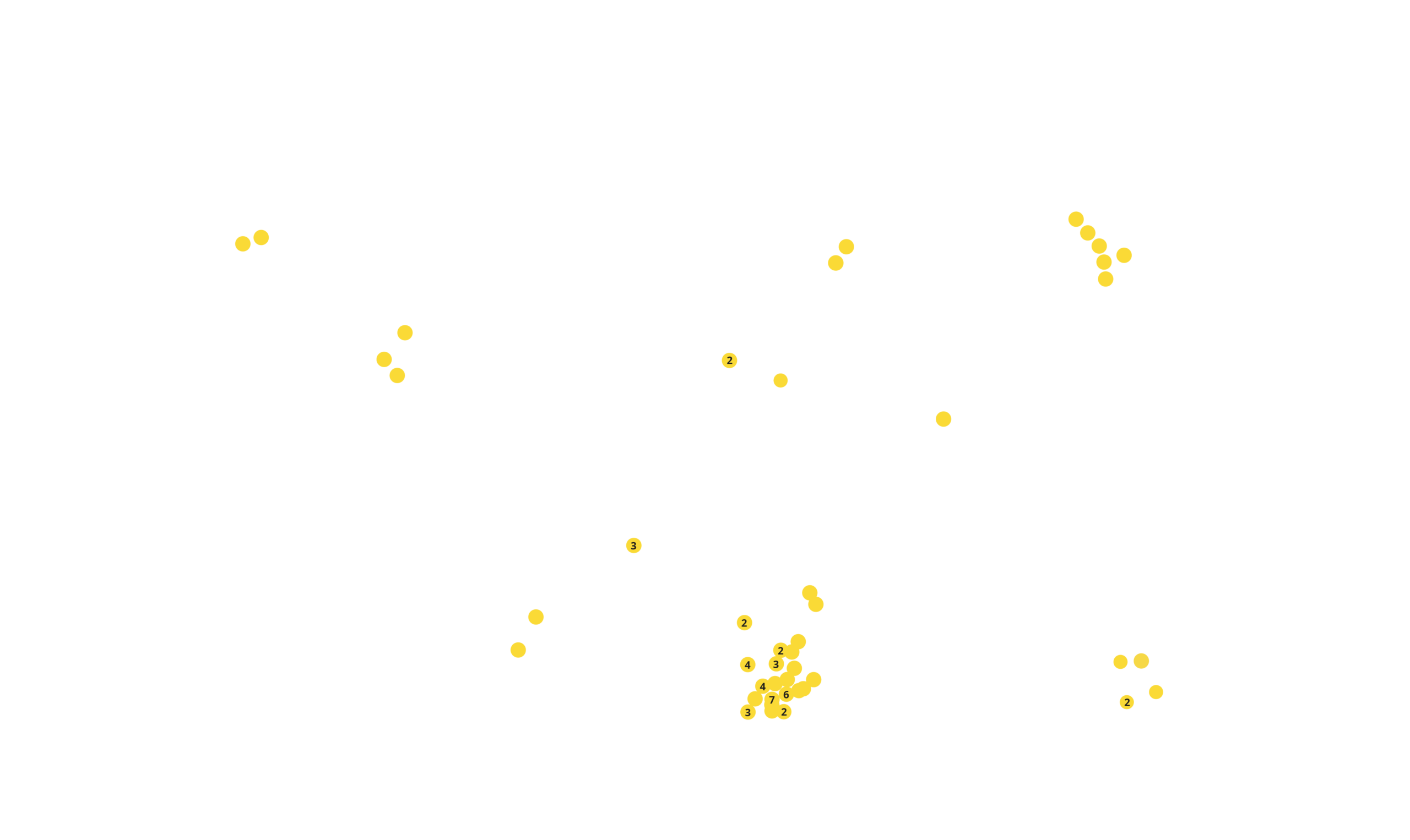

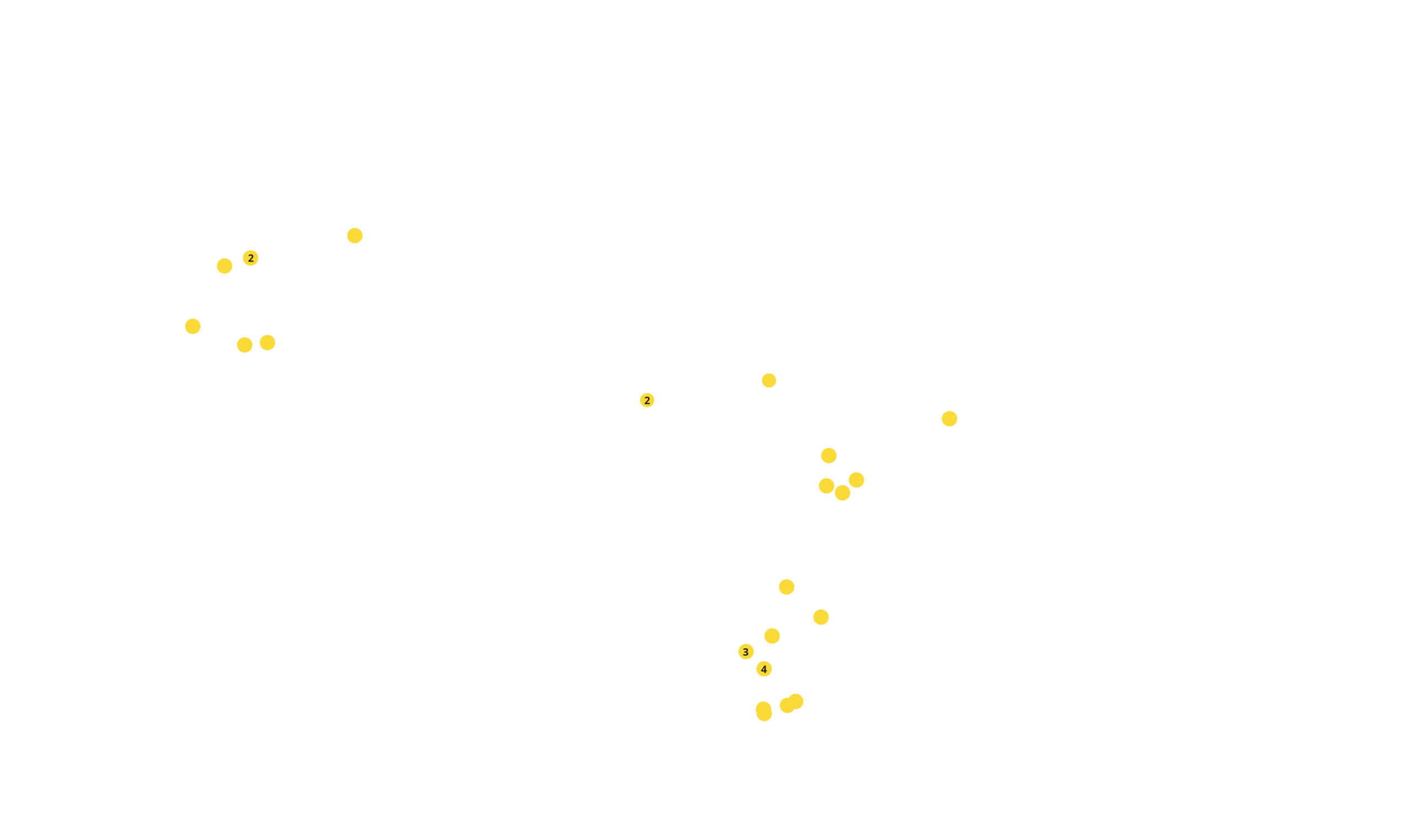

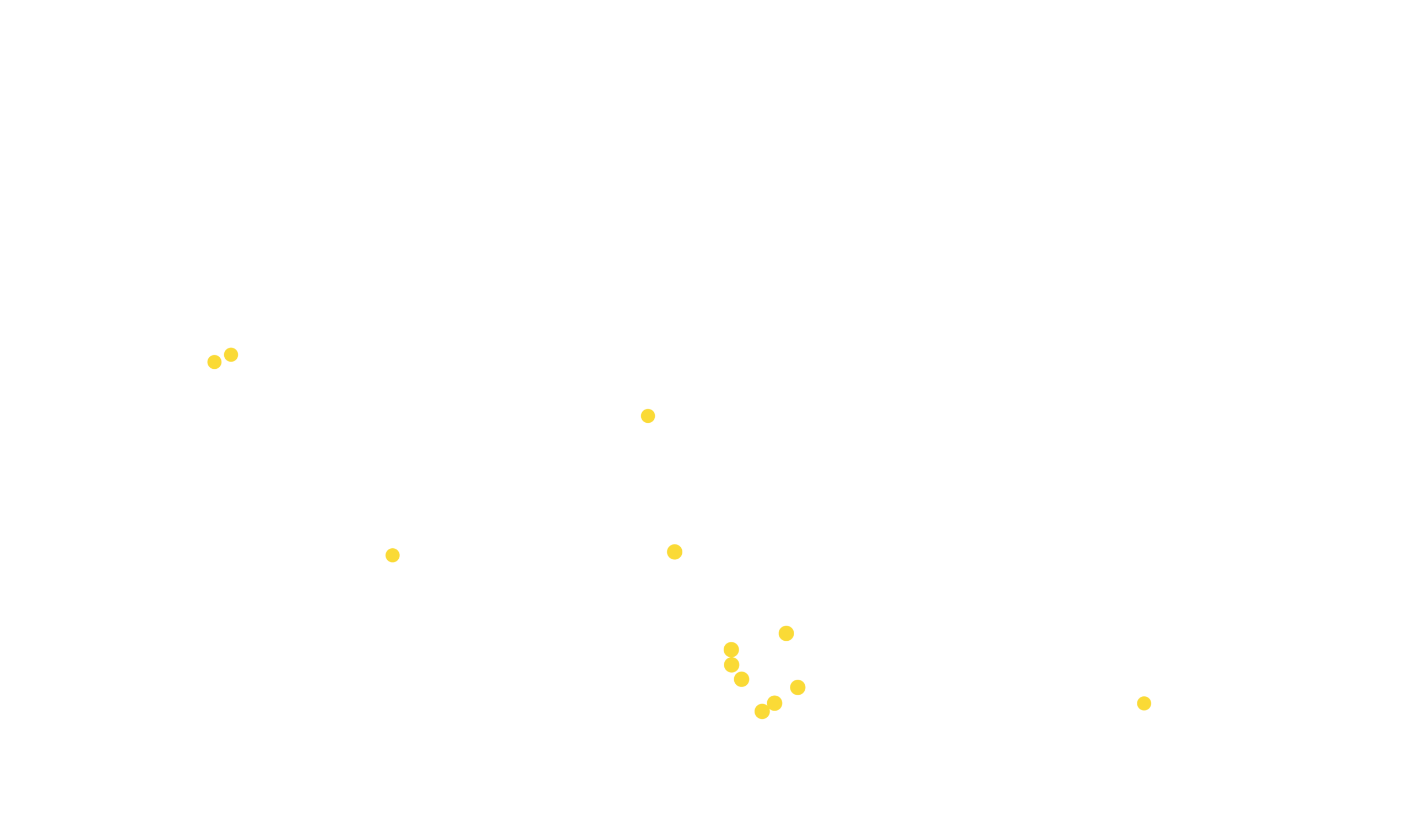

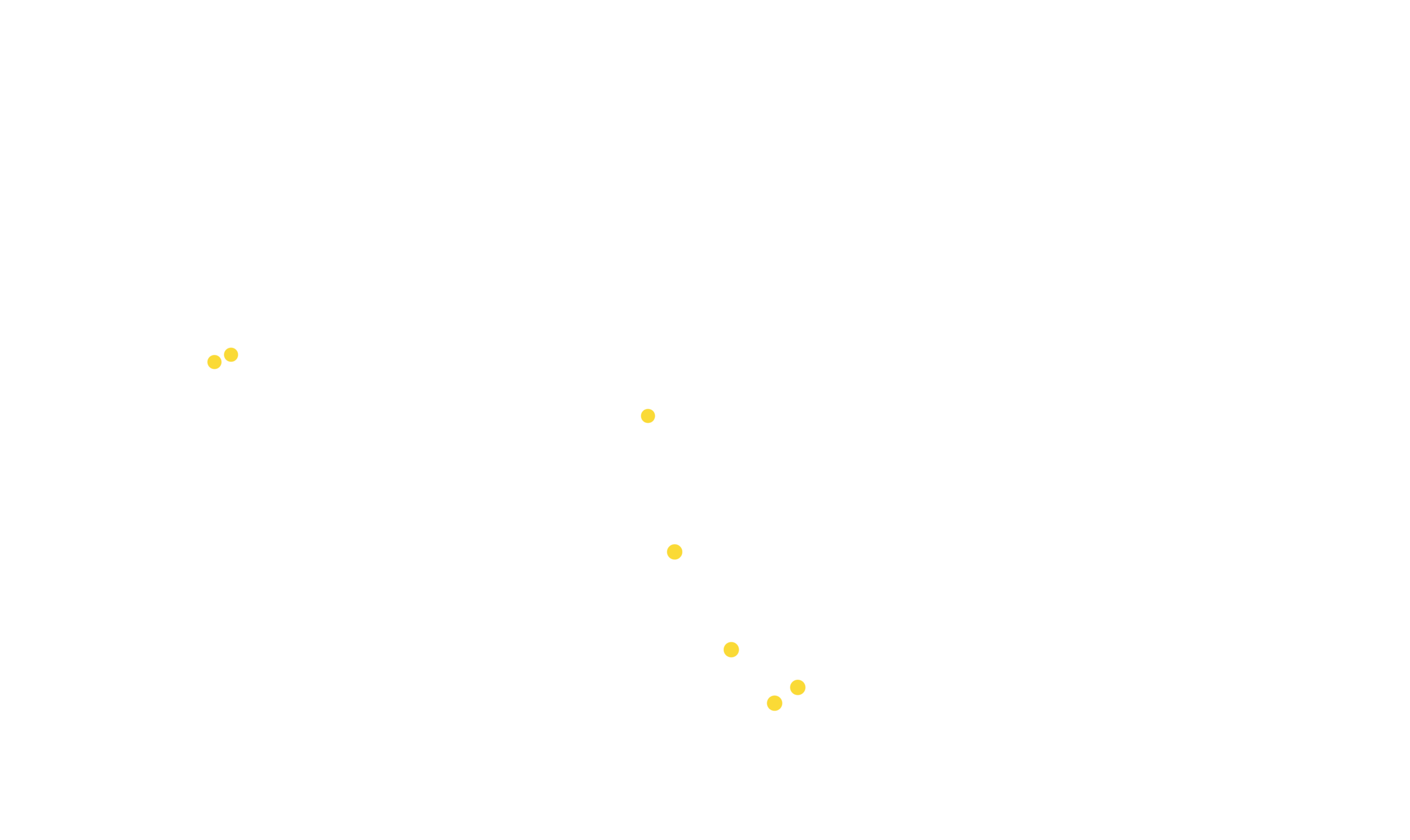

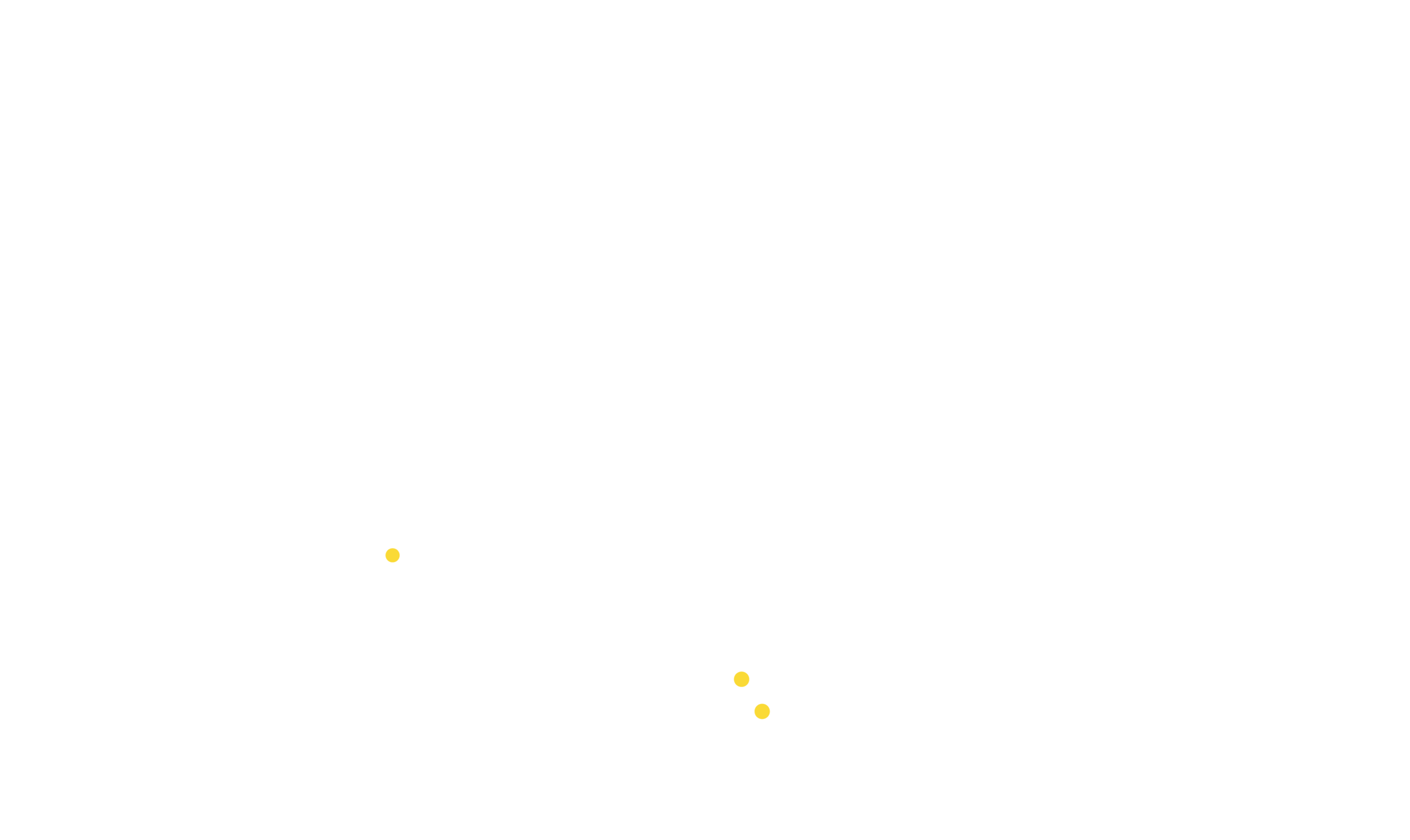

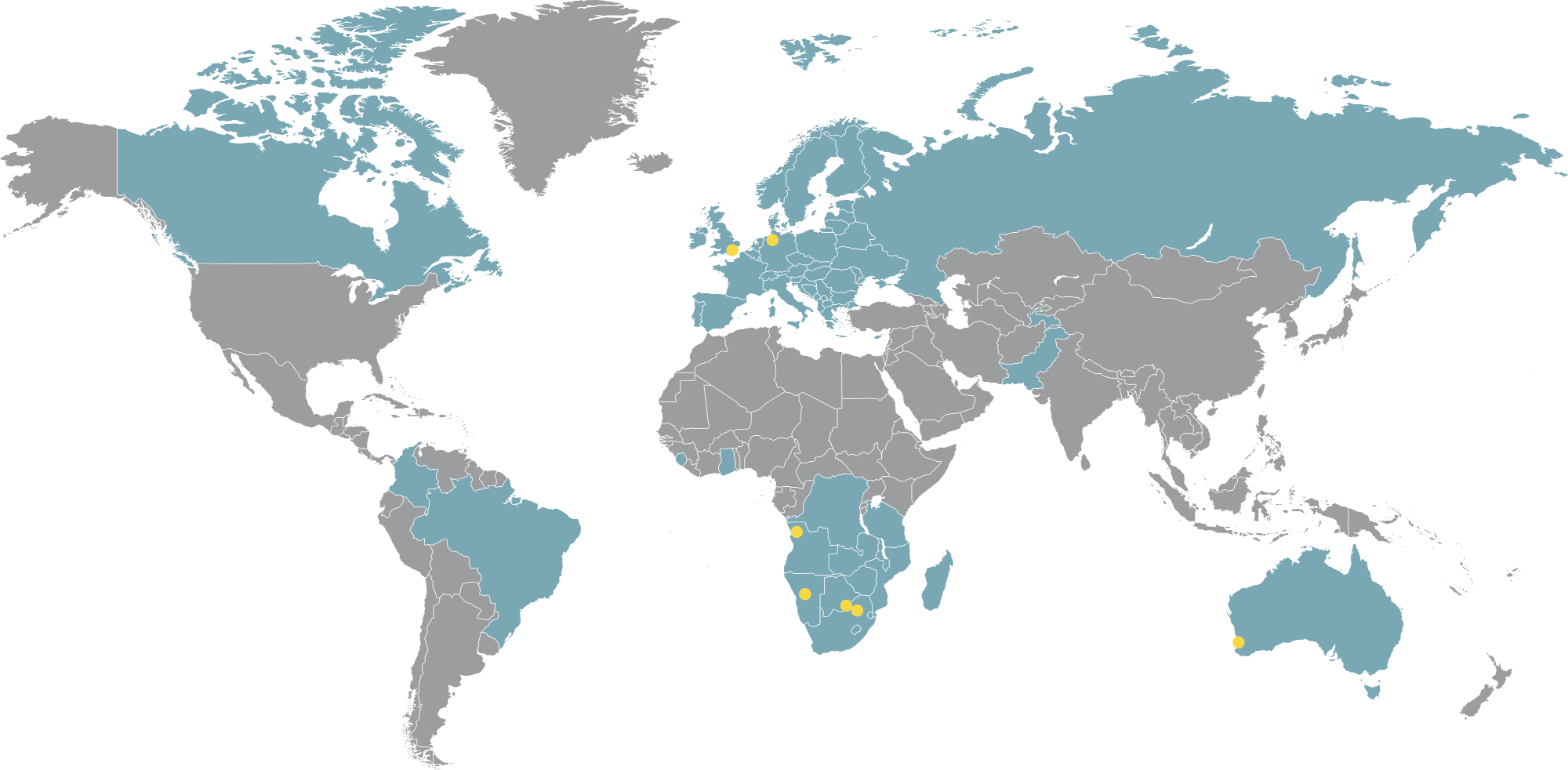

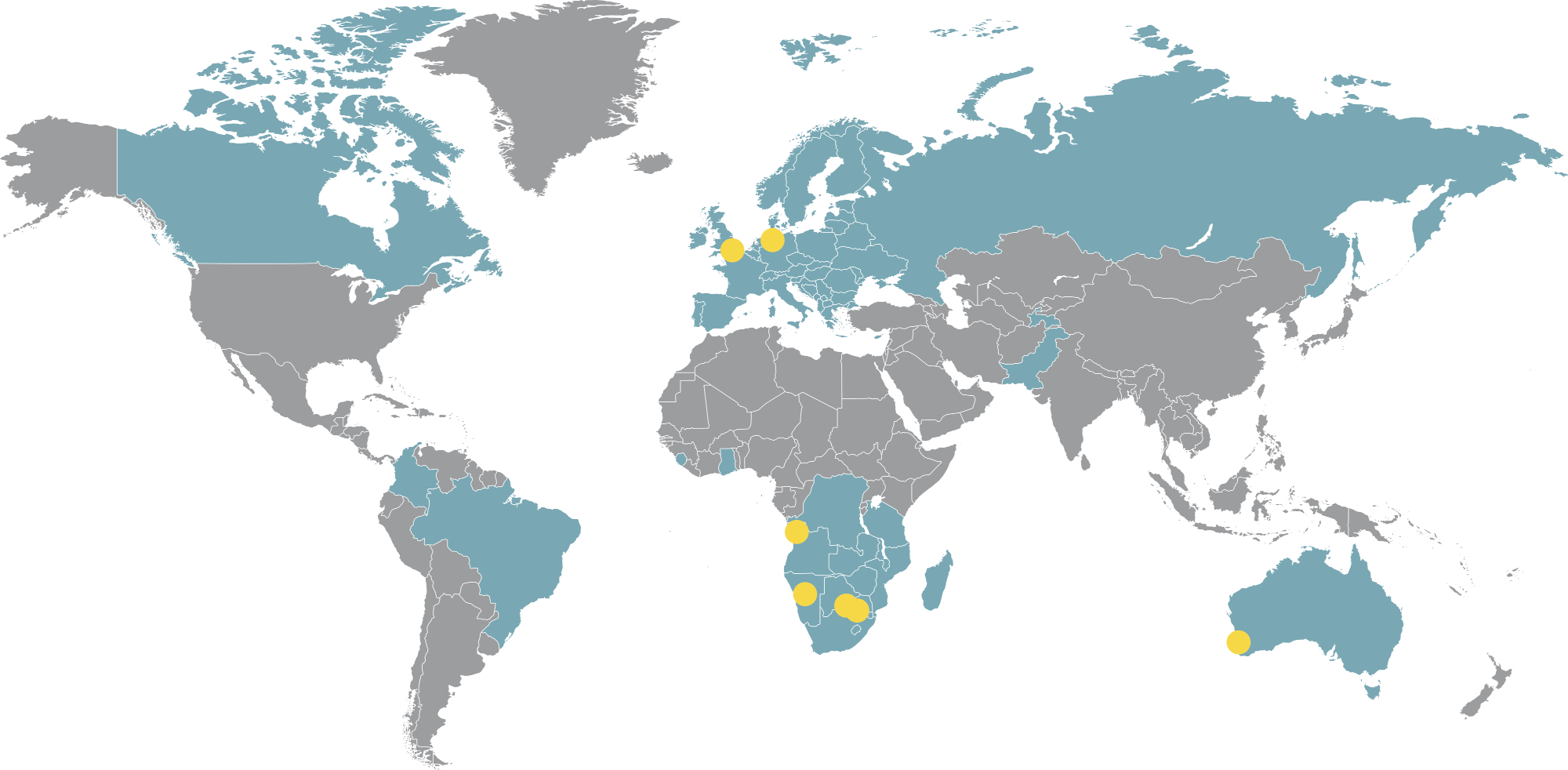

We have helped deliver better project results in

During their careers, STARK employees have completed more than 100 projects worldwide, showcasing a comprehensive portfolio of installations, studies, and client-specific test work. Fuelled by a commitment to excellence, we bring a wealth of hands-on experience to every project. We have earned the trust of clients seeking reliable and innovative solutions. Partner with us to benefit from our proven track record in driving success across diverse mining projects on a global scale.

Our dynamic team has extensive global experience in diverse ore bodies and commodities that spans continents, encompassing a wide spectrum of geological formations and mineral resources. With a proven track record, we excel in navigating the complexities of various mining landscapes, ensuring efficient extraction and optimal resource utilisation. STARK is committed to delivering innovative solutions, leveraging our in-depth knowledge to drive success in the ever-evolving mining industry.

STARK offices

STARK projects

STARK officesSTARK projects

Locations worldwide

Contact us