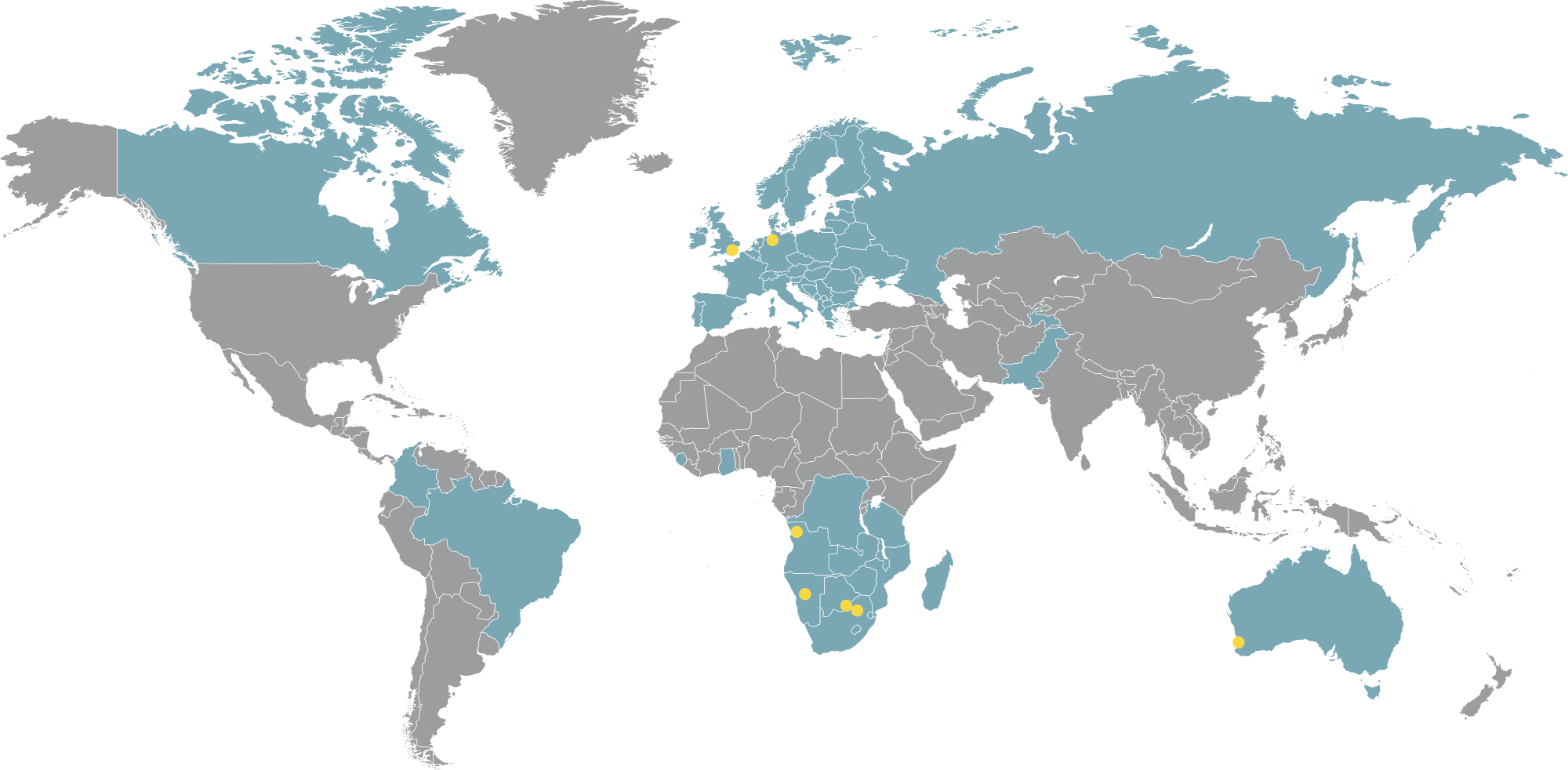

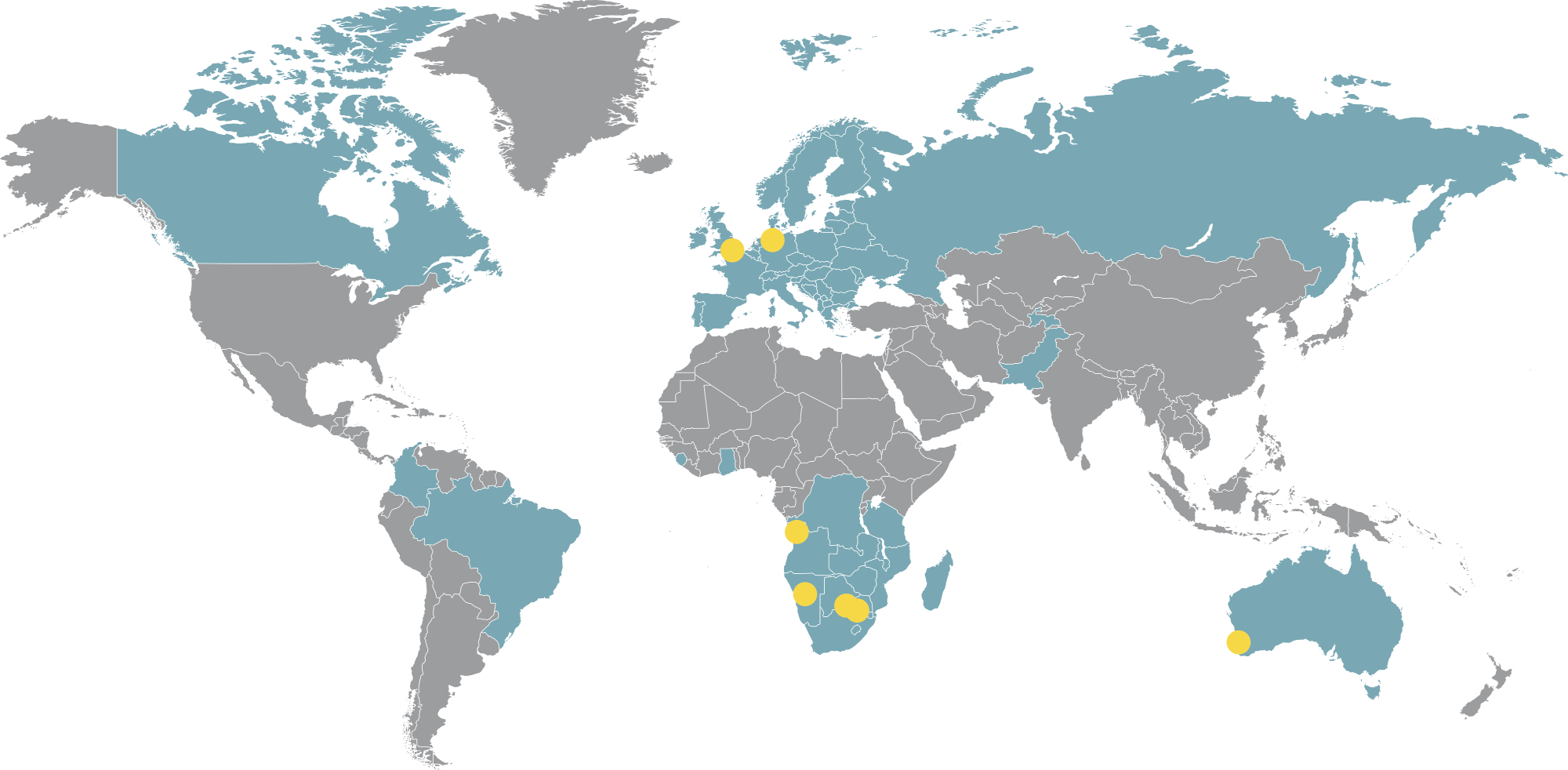

Our dynamic team has extensive global experience in diverse ore bodies and commodities that spans continents and encompasses a wide spectrum of geological formations and mineral resources. With a proven track record, we excel in navigating the complexities of various mining landscapes, ensuring efficient extraction and optimal resource utilisation.

During their careers, STARK employees have completed more than 100 projects worldwide, showcasing a comprehensive portfolio of installations, studies, and client-specific test work. Fuelled by a commitment to excellence, we bring a wealth of hands-on experience to every project. We have earned the trust of clients seeking reliable and innovative solutions.

Our dynamic team has extensive global experience in diverse ore bodies and commodities that spans continents and encompasses a wide spectrum of geological formations and mineral resources. With a proven track record, we excel in navigating the complexities of various mining landscapes, ensuring efficient extraction and optimal resource utilisation.

During their careers, STARK employees have completed more than 100 projects worldwide, showcasing a comprehensive portfolio of installations, studies, and client-specific test work. Fuelled by a commitment to excellence, we bring a wealth of hands-on experience to every project. We have earned the trust of clients seeking reliable and innovative solutions.

Selected STARK Projects

STARK is committed to delivering innovative solutions, leveraging our in-depth knowledge to drive success in the ever-evolving mining industry.

STARK Projects

North America, Canada

Gold

We conducted a comprehensive study for the integration of an XRT ore sorting plant into an underground gold mine in Canada. This study involved the full design of the plant, including detailed estimates of both CAPEX and OPEX. Techno-economic evaluations was performed to assess the viability of the project.

Capabilities

+ Test work

+ Sorter integration

+ Flowsheet simulation

+ Test work design

North America, Canada

Gold

We conducted a comprehensive study for the integration of an XRT ore sorting plant into an underground gold mine in Canada. This study involved the full design of the plant, including detailed estimates of both CAPEX and OPEX. Techno-economic evaluations was performed to assess the viability of the project.

Capabilities

+ Test work

+ Sorter integration

+ Flowsheet simulation

+ Test work design

Europe, Spain

Tin / Tungsten

A comprehensive due diligence and gap analysis for the restart of a tin/tungsten plant and underground mining operations in Western Spain, including CAPEX and OPEX requirements for refurbishment and the integration of ore sorting for enhanced processing efficiency. On another project we conducted an economic assessment of a 10 tph modular spirals gravity plant, analysing the feasibility and financial implications of the project.

Capabilities

+ Metallurgical audits

+ Underground setups Project

Europe, Spain

Tin / Tungsten

A comprehensive due diligence and gap analysis for the restart of a tin/tungsten plant and underground mining operations in Western Spain, including CAPEX and OPEX requirements for refurbishment and the integration of ore sorting for enhanced processing efficiency. On another project we conducted an economic assessment of a 10 tph modular spirals gravity plant, analysing the feasibility and financial implications of the project.

Capabilities

+ Metallurgical audits

+ Underground setups

South America, Colombia

Gold

An Ore Sorting Integration Study with sample selection to initiate an economic tradeoff study. We assessed the feasibility of implementing XRT and laser ore sorting technologies to remove waste material and preconcentrate gold and copper-bearing ore.

Capabilities

+ Feasibility study

+ Test work execution

+ Preliminary plant design

South America, Colombia

Gold

An Ore Sorting Integration Study with sample selection to initiate an economic tradeoff study. We assessed the feasibility of implementing XRT and laser ore sorting technologies to remove waste material and preconcentrate gold and copper-bearing ore.

Capabilities

+ Feasibility study

+ Test work execution

+ Preliminary plant design

Africa, Botswana

Diamond

After nearly six years of effective XRT sorting operations at a diamond mine in Botswana, the XRT Sorters were on the brink of failure due to severe corrosion. In response, five XRT Sorters were replaced with new stainless steel XRT Sorters, along with ancillary upgrades. These replacement and upgrade efforts were carried out during three consecutive shutdowns and were accomplished promptly and within the allocated budget.

Capabilities

+ Retrofit sorters into existing operation

+ Expediting commissioning

Africa, Botswana

Diamond

After nearly six years of effective XRT sorting operations at a diamond mine in Botswana, the XRT Sorters were on the brink of failure due to severe corrosion. In response, five XRT Sorters were replaced with new stainless steel XRT Sorters, along with ancillary upgrades. These replacement and upgrade efforts were carried out during three consecutive shutdowns and were accomplished promptly and within the allocated budget.

Capabilities

+ Retrofit sorters into existing operation

+ Expediting commissioning

Kalgoorlie, Western Australia

Lithium

Implementation of ore sorting technology, conducting a high-level design for an 8 XRT sorter plant aimed at waste removal. The project involved detailed planning and design to enhance the efficiency of waste removal, optimising resource utilisation and operational performance at the mine.

Capabilities

+ Full-scale plant operation integration

Kalgoorlie, Western Australia

Lithium

Implementation of ore sorting technology, conducting a high-level design for an 8 XRT sorter plant aimed at waste removal. The project involved detailed planning and design to enhance the efficiency of waste removal, optimising resource utilisation and operational performance at the mine.

Capabilities

+ Full-scale plant operation integration

Central Asia, Tajikistan

Fluorspar

The design and execution of a Fluorspar flotation plant capable of processing 7,000 tonnes per month. Our team spearheaded the construction and execution phases, leveraging cutting-edge technologies such as 3D scanning to optimise brownfields and enhance plant design.

Capabilities

+ Recommissioning past plants

Central Asia, Tajikistan

Fluorspar

The design and execution of a Fluorspar flotation plant capable of processing 7,000 tonnes per month. Our team spearheaded the construction and execution phases, leveraging cutting-edge technologies such as 3D scanning to optimise brownfields and enhance plant design.

Capabilities

+ Recommissioning past plants

Africa, South Africa

Lithium

A scoping study for a lithium mine with a primary focus on ore sorting operations. We conducted XRT and UV testing to assess the feasibility of integrating sorting technology and rapidly deployed an XRT integrated plant in 6 weeks to remove waste material, surpassing nameplate capacity expectations.

Capabilities

+ Economic trade-off studies

+ Expedited XRT plant deployment

Africa, South Africa

Lithium

A scoping study for a lithium mine with a primary focus on ore sorting operations. We conducted XRT and UV testing to assess the feasibility of integrating sorting technology and rapidly deployed an XRT integrated plant in 6 weeks to remove waste material, surpassing nameplate capacity expectations.

Capabilities

+ Economic trade-off studies

+ Expedited XRT plant deployment

Africa, Tanzania

Waste rejection – Gold

We spearheaded the design and execution of an XRT plant in Tanzania. After assessing the feasibility, we integrated an XRT sorter into a comprehensive pilot plant solution, allowing for remote operation in challenging environments.

Capabilities

+ Expedited pilot plant deployment

+ Rapid commissioning in remote locations

Africa, Tanzania

Waste rejection – Gold

We spearheaded the design and execution of an XRT plant in Tanzania. After assessing the feasibility, we integrated an XRT sorter into a comprehensive pilot plant solution, allowing for remote operation in challenging environments.

Capabilities

+ Expedited pilot plant deployment

+ Rapid commissioning in remote locations

Australia, Australia

Diamonds

Comprehensive study for the integration of an XRT ore sorting plant into an underground gold mine in Canada. This study involved the full design of the plant, including detailed estimates of both CAPEX and OPEX. Techno-economic evaluations was performed to assess the viability of the project.

Capabilities

+ Feasibility study

+ Detailed engineering

+ Plant supply and logistics

+ Feasibility study

+ Construction

+ Sorter integration

+ Commissioning

Australia, Australia

Diamonds

A comprehensive study for the integration of an XRT ore sorting plant into an underground gold mine in Canada. This study involved the full design of the plant, including detailed estimates of both CAPEX and OPEX. Techno-economic evaluations was performed to assess the viability of the project.

Capabilities

+ Feasibility study

+ Detailed engineering

+ Plant supply and logistics

+ Construction

+ Sorter integration

+ Commissioning

Africa, Lesotho

Diamonds

STARK integrated an XRT coarse tailings re-treatment facility to recover large diamonds missed by the existing recovery circuit. This facility successfully recovered the 910ct Lesotho Legend, the largest and most valuable diamond ever found in Lesotho.

Capabilities

+ Feasibility plant design

+ Sorter integration

Africa, Lesotho

Diamonds

STARK integrated an XRT coarse tailings re-treatment facility to recover large diamonds missed by the existing recovery circuit. This facility successfully recovered the 910ct Lesotho Legend, the largest and most valuable diamond ever found in Lesotho.

Capabilities

+ Feasibility plant design

+ Sorter integration

Africa, Botswana

Diamonds

STARK integrated a turn-key diamond laser sorting plant to develop a new diamond recovery application for detecting attached diamonds. This trial project involved installing the plant into the existing recovery system, processing material online, and returning it to the circuit, enhancing the detection and recovery process.

Capabilities

+ Test work design

+ Test work

+ Flowsheet simulation

+ Sorter integration

Africa, Botswana

Diamonds

STARK integrated a turn-key diamond laser sorting plant to develop a new diamond recovery application for detecting attached diamonds. This trial project involved installing the plant into the existing recovery system, processing material online, and returning it to the circuit, enhancing the detection and recovery process.

Capabilities

+ Test work design

+ Test work

+ Flowsheet simulation

+ Sorter integration

Africa, South Africa

Diamonds

STARK integrated a 120tph XRT coarse diamond recovery audit plant to recover large diamonds missed by current technology. Despite COVID challenges, the project was seamlessly implemented while the 1000tph plant remained operational, ensuring continuous and efficient diamond recovery.

Capabilities

+ Feasibility study

+ Detailed engineering

+ Sorter integration

Africa, South Africa

Diamonds

STARK integrated a 120tph XRT coarse diamond recovery audit plant to recover large diamonds missed by current technology. Despite COVID challenges, the project was seamlessly implemented while the 1000tph plant remained operational, ensuring continuous and efficient diamond recovery.

Capabilities

+ Feasibility study

+ Detailed engineering

+ Sorter integration

Africa, Lesotho

Diamonds

STARK integrated a novel and innovative Diamond Within Kimberlite (DWIK) technology trial plant, showcasing advanced methods for enhancing diamond recovery directly from kimberlite ores. This pioneering approach aims to revolutionize the efficiency and accuracy of diamond extraction processes.

Capabilities

+ Feasibility study

+ Detailed Engineering

+ Plant supply and execution

+ commissioning

Africa, Lesotho

Diamonds

STARK integrated a novel and innovative Diamond Within Kimberlite (DWIK) technology trial plant, showcasing advanced methods for enhancing diamond recovery directly from kimberlite ores. This pioneering approach aims to revolutionize the efficiency and accuracy of diamond extraction processes.

Capabilities

+ Feasibility study

+ Detailed Engineering

+ Plant supply and execution

+ Commissioning

Africa, Lesotho

Diamonds

STARK integrated the first TOMRA COM XRT 300 final recovery sorter in a diamond tailings re-treatment project, aimed at recovering fine diamonds. This innovative technology enhances the efficiency and effectiveness of diamond recovery from tailings, setting a new standard in the industry.

Capabilities

+ Flowsheet simulation

+ Sorter integration

Africa, Lesotho

Diamonds

STARK integrated the first TOMRA COM XRT 300 final recovery sorter in a diamond tailings re-treatment project, aimed at recovering fine diamonds. This innovative technology enhances the efficiency and effectiveness of diamond recovery from tailings, setting a new standard in the industry.

Capabilities

+ Flowsheet simulation

+ Sorter integration

Africa, Botswana

Diamonds

STARK replaced four XRT sorters crucial to diamond recovery during a standard maintenance shutdown. This complex task, complicated by COVID, was executed seamlessly, showcasing STARK's expertise in performing intricate unit recovery process replacements in brownfield operations without disrupting plant operations.

Capabilities

+ Flowsheet simulation

+ Detailed Engineering

+ Integration of five sorters

Africa, Lesotho

Diamonds

STARK replaced four XRT sorters crucial to diamond recovery during a standard maintenance shutdown. This complex task, complicated by COVID, was executed seamlessly, showcasing STARK's expertise in performing intricate unit recovery process replacements in brownfield operations without disrupting plant operations.

Capabilities

+ Flowsheet simulation

+ Detailed Engineering

+ Integration of five sorters

Our clients and partners say

We're so happy to be working with Stark Resources. We're impressed by their competence, experience, dedication, and their ability to think outside the box and solve problems. Very important for early stage and low-cost oriented companies like ours, operating in challenging environments.

Thomas Häggkvist

CEO Africa Resources

We acquired an updated stand-alone XRT plant and within a very short space of time recovered the 91O ct D-colour Lesotho Legend diamond at Letšeng. This must surely rank as one of the best ROIs that has ever been seen!

Clifford Elphick

Chief Executive Officer

Stark has enhanced and vastly improved our XRT sensor-based sorting and tracer testing for primary diamond recovery with bench scale test work, field testing and the full scale implementation of automatic, remote RFID tracer systems. This innovative approach provides further process assurance in real time.

John Armstrong

Vice President Technical Services

STARK offices

STARK projects

STARK officesSTARK projects

Locations worldwide

Contact us