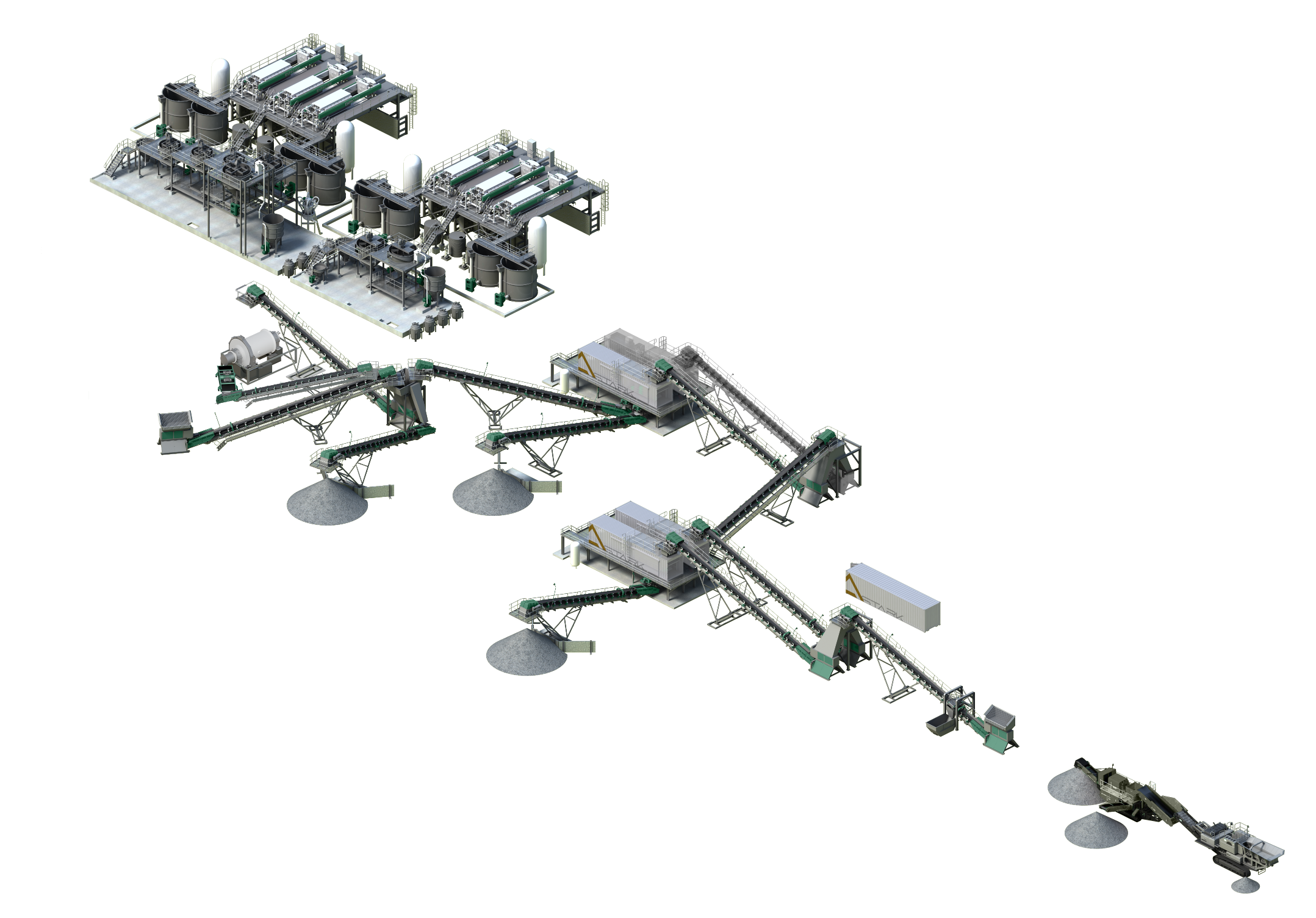

STARK Resources has designed and built large-scale Greenfield pilot plants in remote bush or outback with little access to infrastructure or a specialised workforce for many clients over the past 10 years.

The advantages of building a large-scale plant

The beauty of our modular pilot plant approach is that the team can start by installing the minimum necessary components and then add further modules as necessary. This helps limit costs for the client – a key consideration as most exploratory miners are constrained by financing.

The advantages of building a large-scale plant

The beauty of our modular pilot plant approach is that the team can start by installing the minimum necessary components and then add further modules as necessary. This helps limit costs for the client – a key consideration as most exploratory miners are constrained by financing.

+

FIXED-COST INVESTMENT

Outlay of circa US$40 million, on a fixed-cost basis.

+

FAST-TRACK CONSTRUCTION

Expedited build time, in as little as nine months.

+

DAY-ONE REVENUE IMPACT

Revenue generating from the first day of handover.

+

RAPID

RETURNS

Enjoy a rapid payback time of capital expenditure.

+

QUICK DEPOSIT VALIDATION

Demonstrate the economic viability of the deposit faster than the traditional routes.

+

EXCLUSIVE TECHNOLOGY

Benefit from state-of-the-art technology prowess not available elsewhere.

+

SKILLS

TRANSFER

We train and support local workers through knowledge transfer.

Recovery techniques on a modular basis

A project size below $50 million is often too little to make clients a priority at larger developers, but STARK specialises in targeting smaller assets with an orebody that lends itself to recovery techniques on a modular basis.

Recovery techniques on a modular basis

A project size below $50 million is often too little to make clients a priority at larger developers, but STARK specialises in targeting smaller assets with an orebody that lends itself to recovery techniques on a modular basis.

Get revenue up and running!

Smaller or mid-tier companies can’t always go down the expensive and lengthy route of developing a pre-feasibility study, a definitive feasibility study, and other considerations that come before finally setting up a processing plant.

Instead, get revenue up and running after some initial mineral characterisation, while also providing the opportunity to learn more about their deposit and make it more attractive for further financing. It all starts with a flowsheet – STARK’s overall personalised in-depth guide to achieve customised project success.

Get revenue up and running!

Smaller or mid-tier companies can’t always go down the expensive and lengthy route of developing a pre-feasibility study, a definitive feasibility study, and other considerations that come before finally setting up a processing plant.

Instead, get revenue up and running after some initial mineral characterisation, while also providing the opportunity to learn more about their deposit and make it more attractive for further financing. It all starts with a flowsheet – STARK’s overall personalised in-depth guide to achieve customised project success.

A complete turnkey solution

Our complete turnkey solution is perfect for operations which have completed a scoping study, or perhaps have started initial work on a Pre-Feasibility Study. These plants are usually funded by an offtake or Joint Venture partner, with a multi-year plan to develop the deposit over time in place.

Contact us

Any questions?

We are always at your service.

Eleanore Luise Forner

Pr. Eng. / B. Eng. Hons (Chem.)

PRINCIPAL – LITHIUM

eleanore@stark-resources.com

+27 82 316 8568