We are world-leading experts in the integration of ore sorting technology.

STARK has the expertise to implement almost every mining technology in the field to brownfield sites. Dense Media Separation (DMS) plants, RFID tracers, selective milling, magnetic separation; whatever your needs, we can deliver. As we are experts in delivering Greenfield plants from scratch, we can enhance and recalibrate virtually every aspect of your plant, delivering huge cost benefits with a rapid payback time.

However, STARK can also deliver some solutions that no other operator can.

The advantages of implementing ore sorting technology at Tier-1 projects:

- Install integrated modular solutions, which can be ready within two weeks of arrival on site

- Deliver rapid payback time, often of only a few months

- Increase minable tons, reclaim waste dumps, divert ore types to access previously inaccessible revenue, decrease haulage costs and reduce tailings

- Reduce water consumption by up to 100%, and energy consumption by up to 80%

- Minimise reagent use

After initial orebody analysis, our focus is on immediate cash benefits, as all improvements which result in an increased yield from the orebody constitute 100% additional profit.

We are world-leading experts in the integration of ore sorting technology.

STARK has the expertise to implement almost every mining technology in the field to brownfield sites. Dense Media Separation (DMS) plants, RFID tracers, selective milling, magnetic separation; whatever your needs, we can deliver. As we are experts in delivering Greenfield plants from scratch, we can enhance and recalibrate virtually every aspect of your plant, delivering huge cost benefits with a rapid payback time.

However, STARK can also deliver some solutions that no other operator can.

The advantages of implementing ore sorting technology at Tier-1 projects:

- Install integrated modular solutions, which can be ready within two weeks of arrival on site

- Deliver rapid payback time, often of only a few months

- Increase minable tons, reclaim waste dumps, divert ore types to access previously inaccessible revenue, decrease haulage costs and reduce tailings

- Reduce water consumption by up to 100%, and energy consumption by up to 80%

- Minimise reagent use

After initial orebody analysis, our focus is on immediate cash benefits, as all improvements which result in an increased yield from the orebody constitute 100% additional profit.

Our clients and partners say

Lucara's Karowe mine stands alone in the global context of large diamond recovery as the only location to recover 4 diamonds larger than 1,000 carats. As an early adaptor of sensor-based primary diamond recovery from sized run of mine material, the Stark Team over the years has been instrumental in the design, process flow, construction and commissioning of the XRT circuits. The results are a testament to incredible team work, excellent process flow, and an innovative circuit combined with a truly unique diamond deposit.

John Armstrong

Vice President Technical Services

We acquired an updated stand-alone XRT plant and within a very short space of time recovered the 91O ct D-colour Lesotho Legend diamond at Letšeng. This must surely rank as one of the best ROIs that has ever been seen!

Clifford Elphick

Chief Executive Officer

During COVID lockdown the team replaced 5 COMS XRT sorters, washing screens along with XRT building expansion. This was planned remotely with the Karowe Process and Engineering teams, and executed on the ground. At the height of the global pandemic this work was completed safely, on time and on budget, under challenging circumstances - a testament to their ability to plan and execute.

John Armstrong

Vice President Technical Services

Ore sorting technologies that are typically implemented

XRT

X-ray transmission (XRT) is a non-destructive technology that uses X-rays to penetrate materials, identifying differences in density and composition.

XRL

X-ray luminescence detection involves using X-rays to excite materials, causing them to emit visible light. This emitted light is analysed to determine the composition and properties of the material.

XRF

X-ray fluorescence (XRF) is used to analyse the elemental composition of ores and minerals.

Colour sorting

Colour sorting uses optical sensors to identify and separate materials based on their colour.

Laser

A laser sensing detection system uses laser beams to detect and measure distances, shapes, or compositions of objects.

Electromagnetic

Eddy current detection uses electromagnetic induction to identify variations in conductive materials.

NIR

NIR (Near-Infrared) sorting uses near-infrared light to identify and separate materials based on their molecular composition.

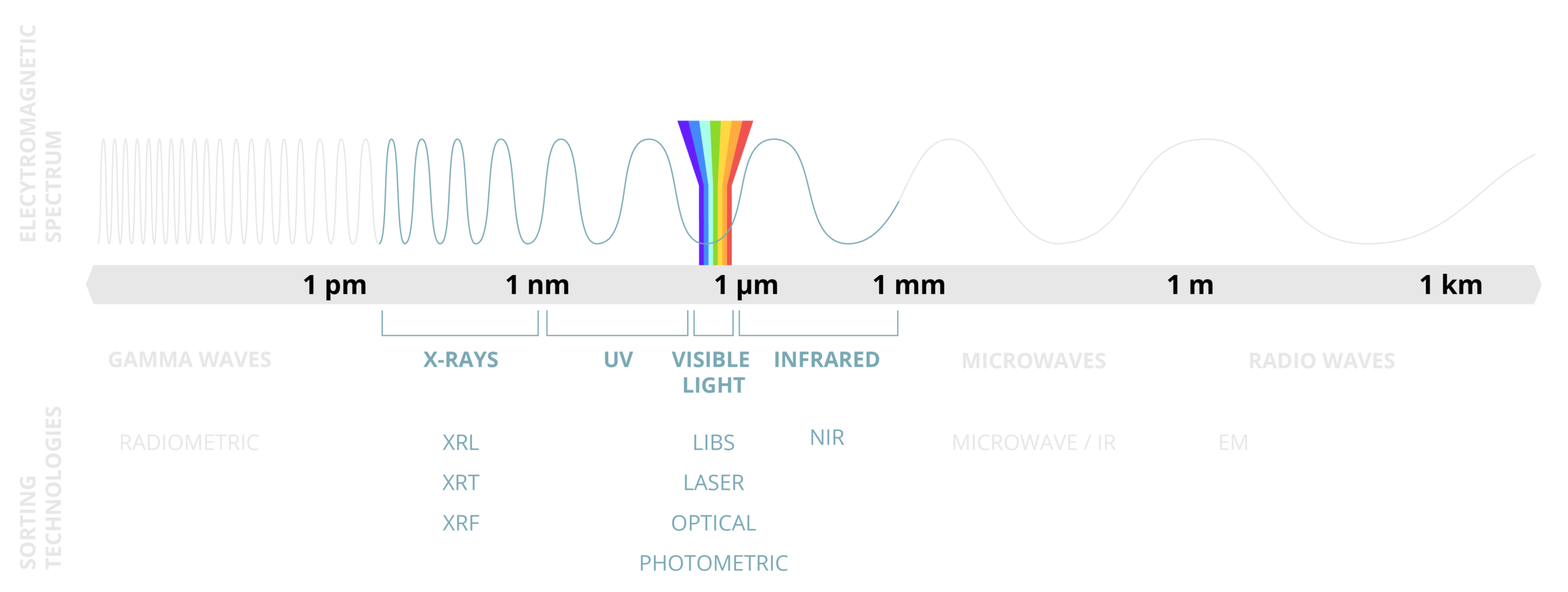

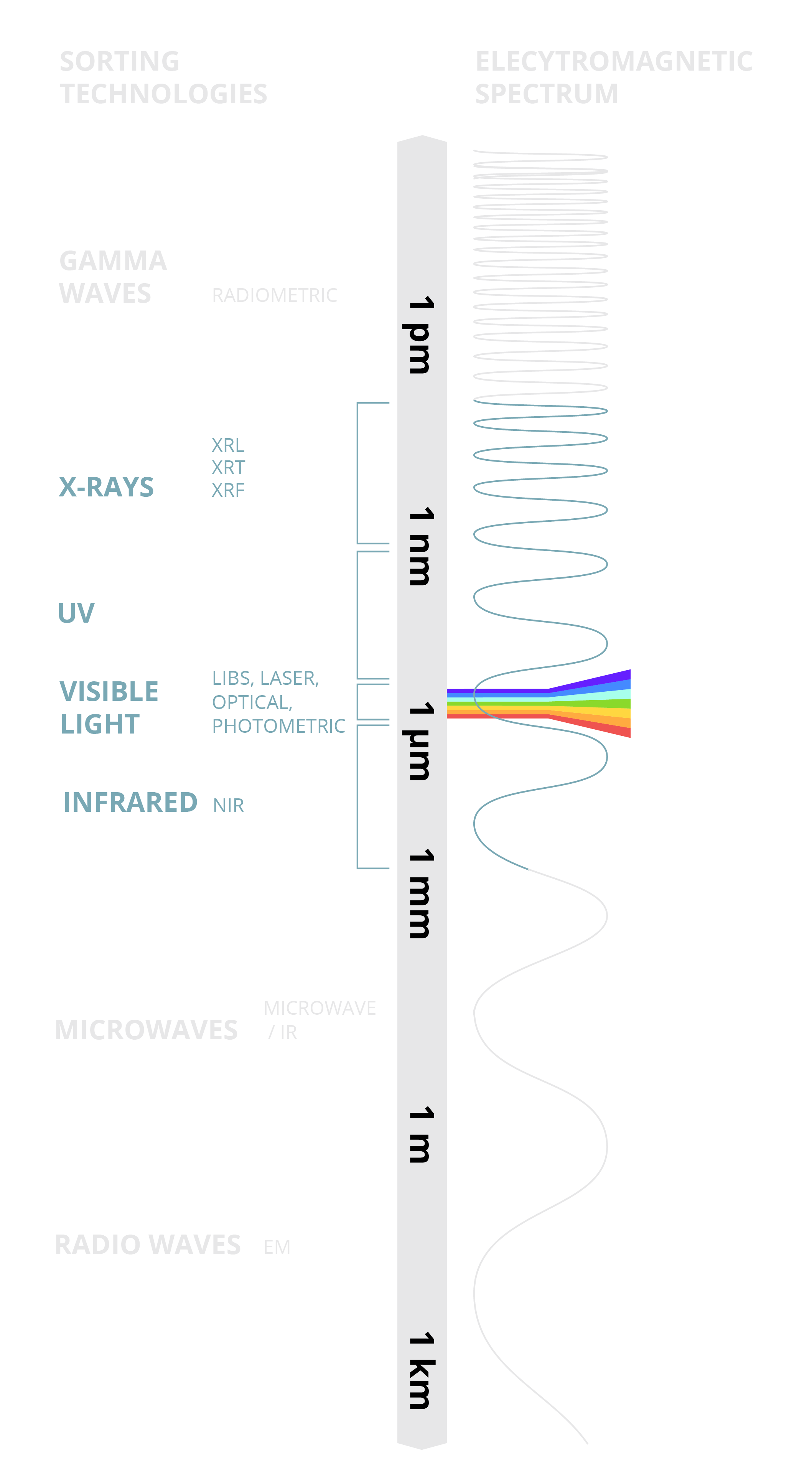

Sensor-based sorting technologies cover the entirety of the electromagnetic spectrum, from radiometric sorting utilising gamma radiation to electromagnetic sorting in the radio wave spectrum.

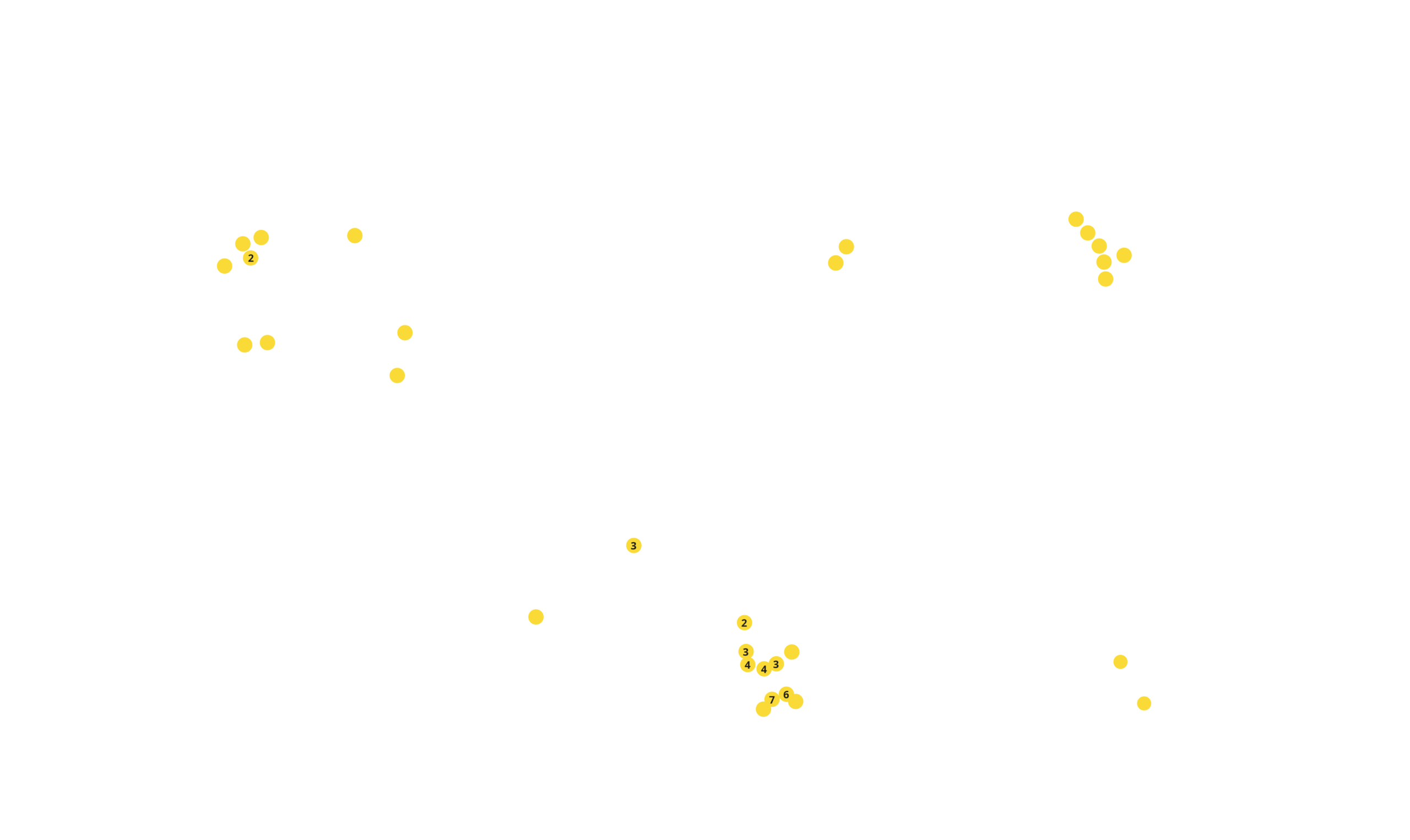

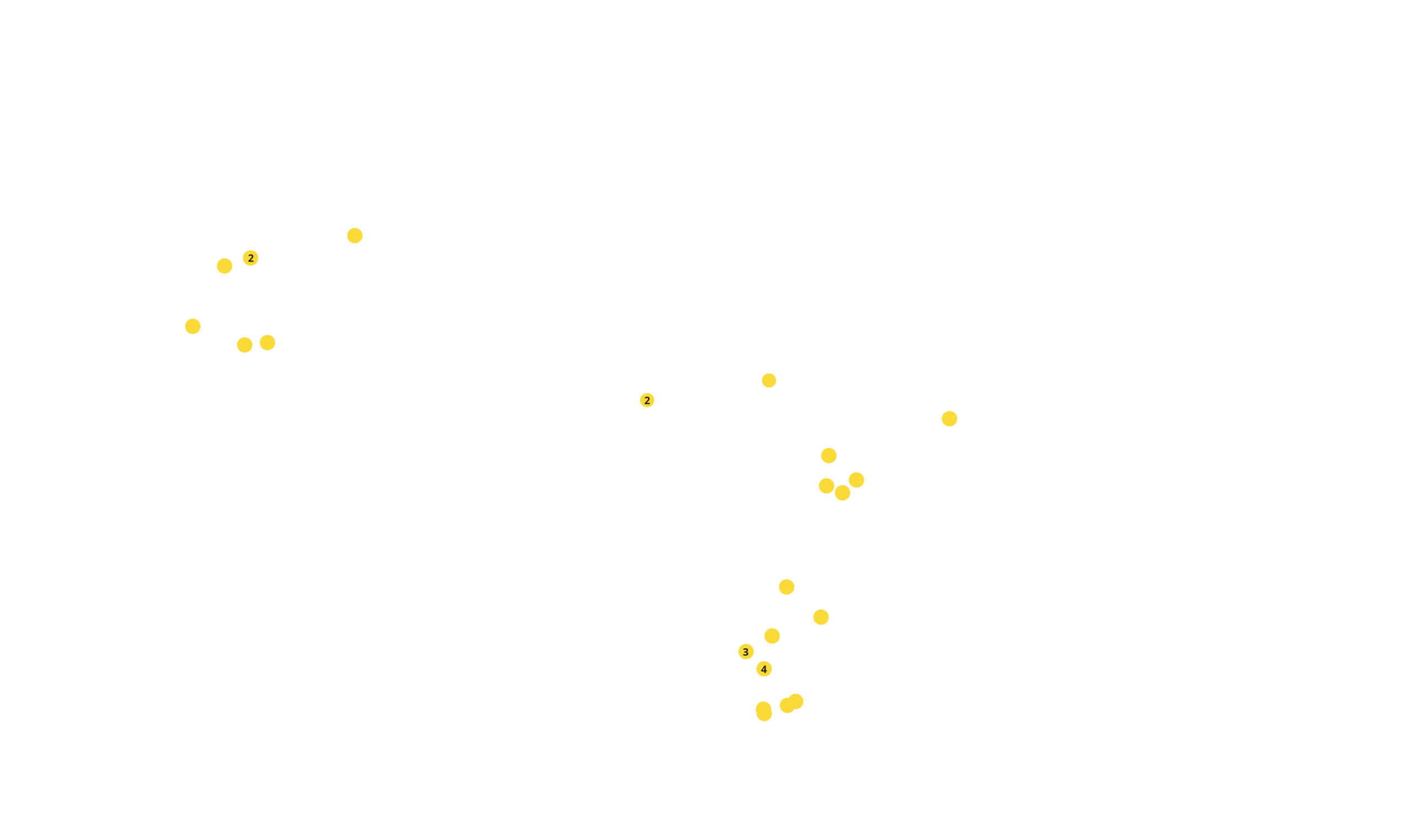

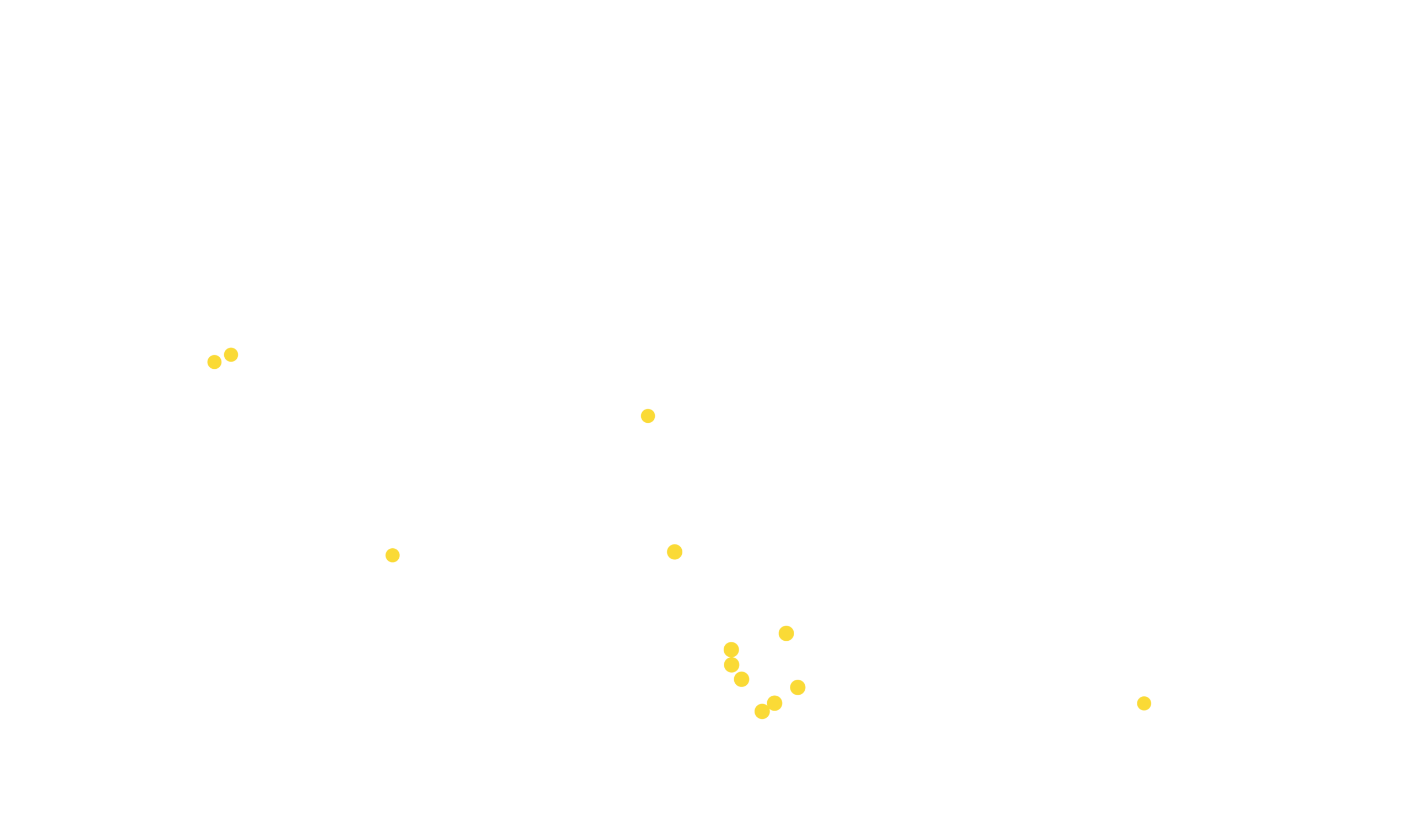

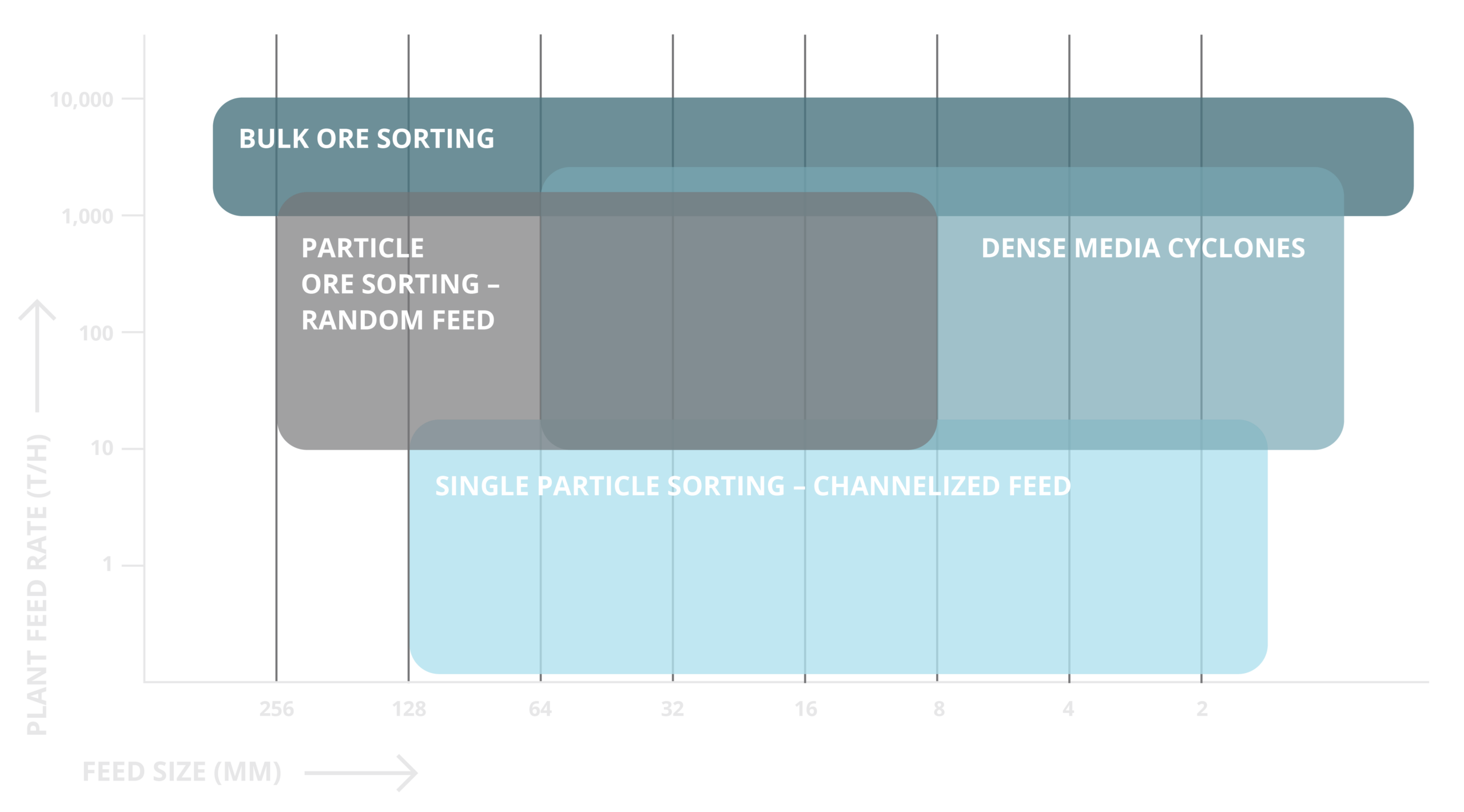

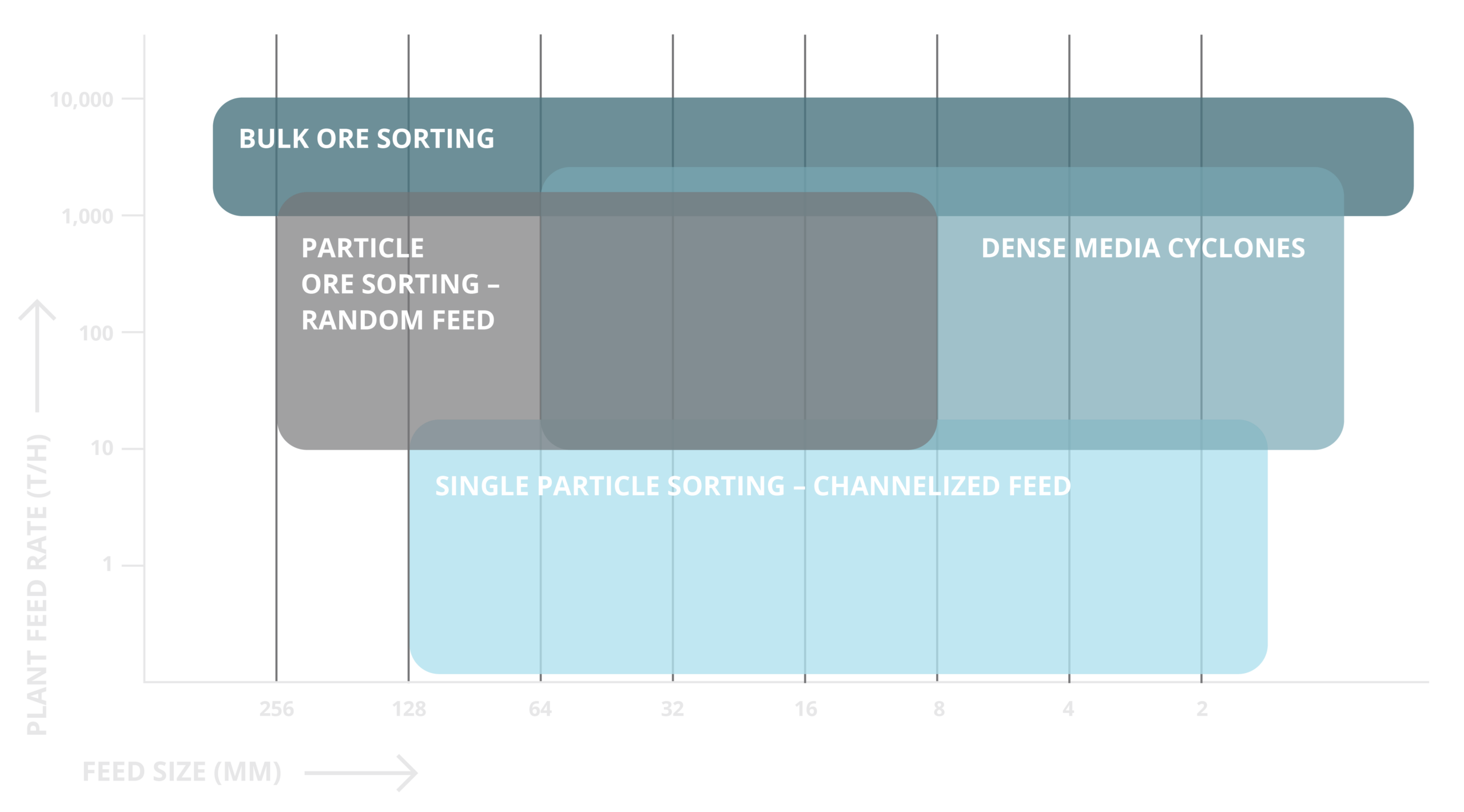

Typical application ranges of sorting technologies in relation to dense media separation (DMS) by plant capacity vs. particle size range.

Sensor-based sorting technologies cover the entirety of the electromagnetic spectrum, from radiometric sorting utilising gamma radiation to electromagnetic sorting in the radio wave spectrum.

Typical application ranges of sorting technologies in relation to dense media separation (DMS) by plant capacity vs. particle size range.

Is a single test sufficient for determining ore sorting suitability in an orebody?

You may be under the misconception that ore sorting suitability can be determined with a single test. The sensors and software advancements available with modern technology are continuously evolving, and many assets have only been tested with one type of ore sorter. STARK uses the most advanced orebody analysis techniques to check whether a different approach might yield positive results. We’re able to source ore sorters from the entire market.

Beyond this, assets need to be comprehensively tested, with multiple samples taken from material including a high, low, and average expected feed. Tier 1 miners may think they need more advanced capacities than STARK can provide, but it’s often the case that only a small segment, or a specific size class, of total feed streams needs to be sorted for value add.

Other objections can include fears that original plant designs didn’t include sorting, or that it adds an extra layer of complexity to a simple, already smooth operation. However, this is another misconception — we independently integrate and apply equipment to reduce downstream chemical processing requirements and tailings, which makes the operation easier as well as cheaper.

At the very least, it’s worth a brief call to see whether we can help.

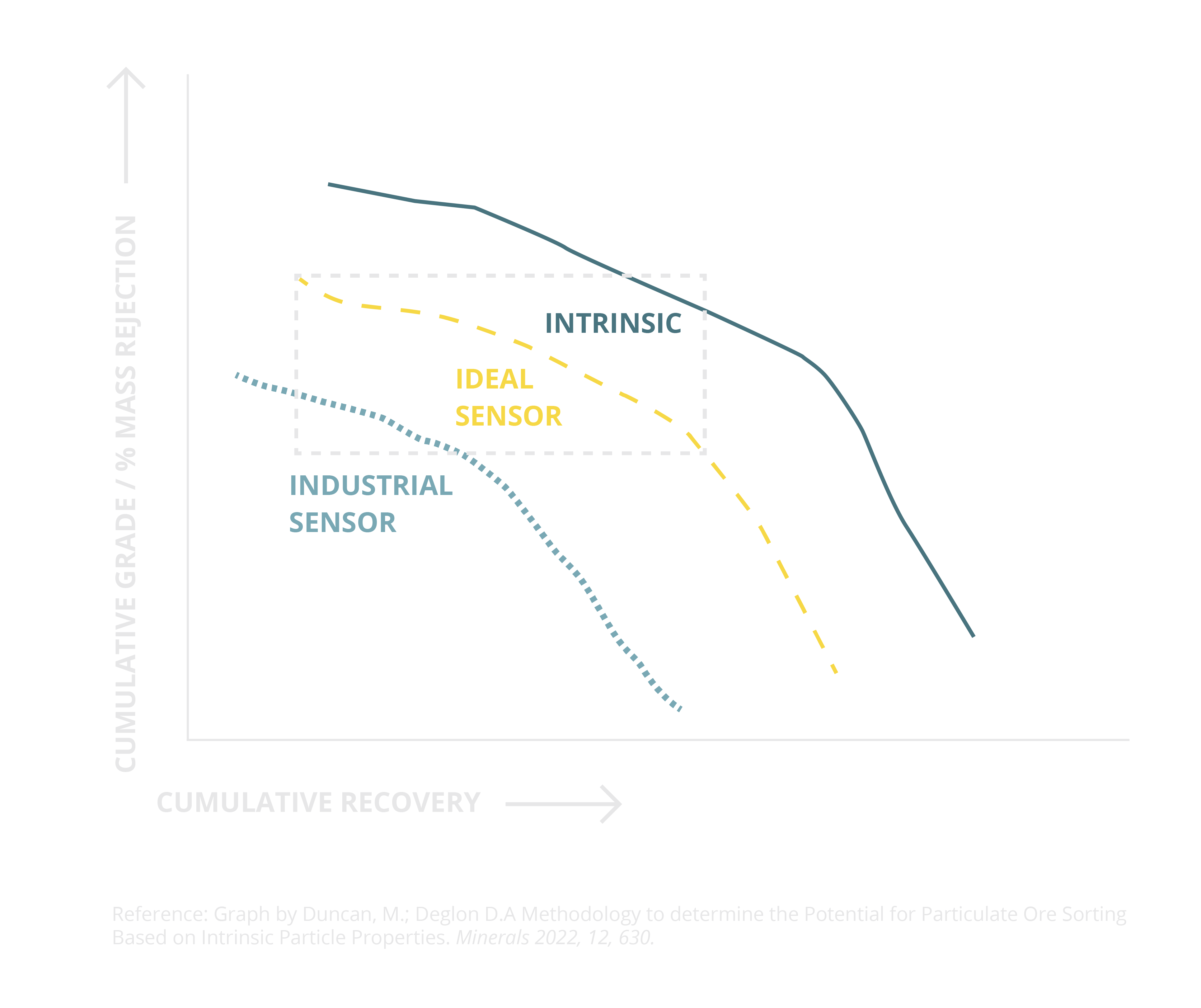

Stages of a process design

Ideation

(definition phase)

Intrinsic sortability testing

+ Heterogeneity analysis

+ Hand sort testing

Concept

design

Ideal sensor sortability

+ Static scanning

+ Dynamic scanning

Front end (FEED)

engineering design

Industrial sensor sortability:

+ Dynamic sorting tests

+ Performance sorting tests

Detailed

Engineering

Industrial sensor sortability (Pilot testing):

+ Pilot plant tests on site

Stages of a process design

Ideation

(definition phase)

Intrinsic sortability testing

+ Heterogeneity analysis

+ Hand sort testing

Concept

design

Ideal sensor sortability

+ Static scanning

+ Dynamic scanning

Front end (FEED)

engineering design

Industrial sensor sortability:

+ Dynamic sorting tests

+ Performance sorting tests

Detailed

Engineering

Industrial sensor sortability (Pilot testing):

+ Pilot plant tests on site

Benefits of working with the STARK team

+

ORE SORTING EXPERTISE

Decades of experience with ore sorting integration in a variety of process flow sheets

+

AGNOSTIC

INSIGHT

Independent / agnostic perspective - independent of other OEMs

+

SCALABLE

DESIGN

Ability to do process design and scale up from lab test work to plant performance.

+

COMPREHENSIVE

GUIDANCE

Can guide the process from PEA and then all the way through to detailed engineering stages.

Benefits of working with the STARK team

+

ORE SORTING EXPERTISE

Decades of experience with ore sorting integration in a variety of process flow sheets

+

AGNOSTIC

INSIGHT

Independent / agnostic perspective - independent of other OEMs.

+

SCALABLE

DESIGN

Ability to do process design and scale up from lab test work to plant performance.

+

COMPREHENSIVE

GUIDANCE

Can guide the process from PEA and then all the way through to detailed engineering stages.

Delivering global project results

During their careers, STARK employees have completed more than 100 projects worldwide, showcasing a comprehensive portfolio of installations, studies, and client-specific test work. Fuelled by a commitment to excellence, we bring a wealth of hands-on experience to every project. We have earned the trust of clients seeking reliable and innovative solutions. Partner with us to benefit from our proven track record in driving success across diverse mining projects on a global scale.

Our dynamic team has extensive global experience in diverse ore bodies and commodities that spans continents, encompassing a wide spectrum of geological formations and mineral resources. With a proven track record, we excel in navigating the complexities of various mining landscapes, ensuring efficient extraction and optimal resource utilisation. STARK is committed to delivering innovative solutions, leveraging our in-depth knowledge to drive success in the ever-evolving mining industry.

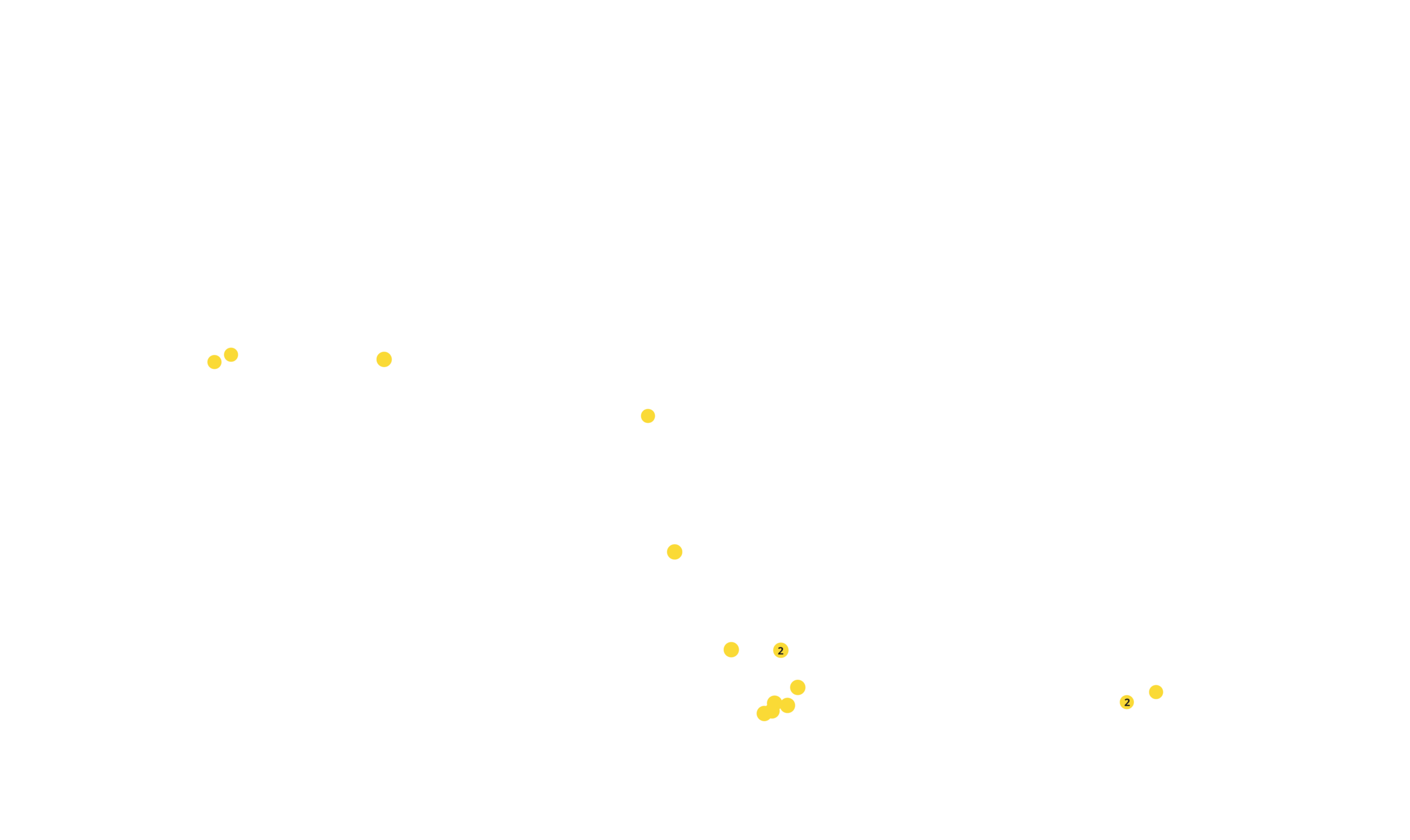

Select Sorting Projects We've Worked On

North America, Canada

Capabilities

+ Test work

+ Sorter integration

+ Flowsheet simulation

+ Test work design

South America, Colombia

Capabilities

+ Feasibility study

+ Test work education

+ Preliminary plant design

Africa, Botswana

Capabilities

+ Retrofit sorters into existing operation

+ Expediting commissioning

Kalgoorlie, Western Australia

Capabilities

+ Full-scale plant operation integration

Africa, South Africa

Capabilities

+ Economic trade-off studies

+ Expedited XRT plant deployment

Africa, Tanzania

Capabilities

+ Expedited pilot plant deployment

+ Rapid commissioning in remote locations

Our ore-sorting experts

Dian Heinrich Page

GROUP HEAD OF ADVISORY

Pr.Sci.Nat / M.Eng Geo Tech

| Germany | |

| +49 1728 170 726 | |

| dian@stark-resources.com |

Fabian Riedel

CHIEF TECHNICAL OFFICER

Dipl.-Ing. Mining Engineering

| Germany | |

| fabian@stark-resources.com |

Contact us

Any questions?

We are always at your service.

Ryan Szabo

B.Tech Mech Engineering

PROJECT MANAGER

ryan@stark-resources.com

+49 177 242 5901