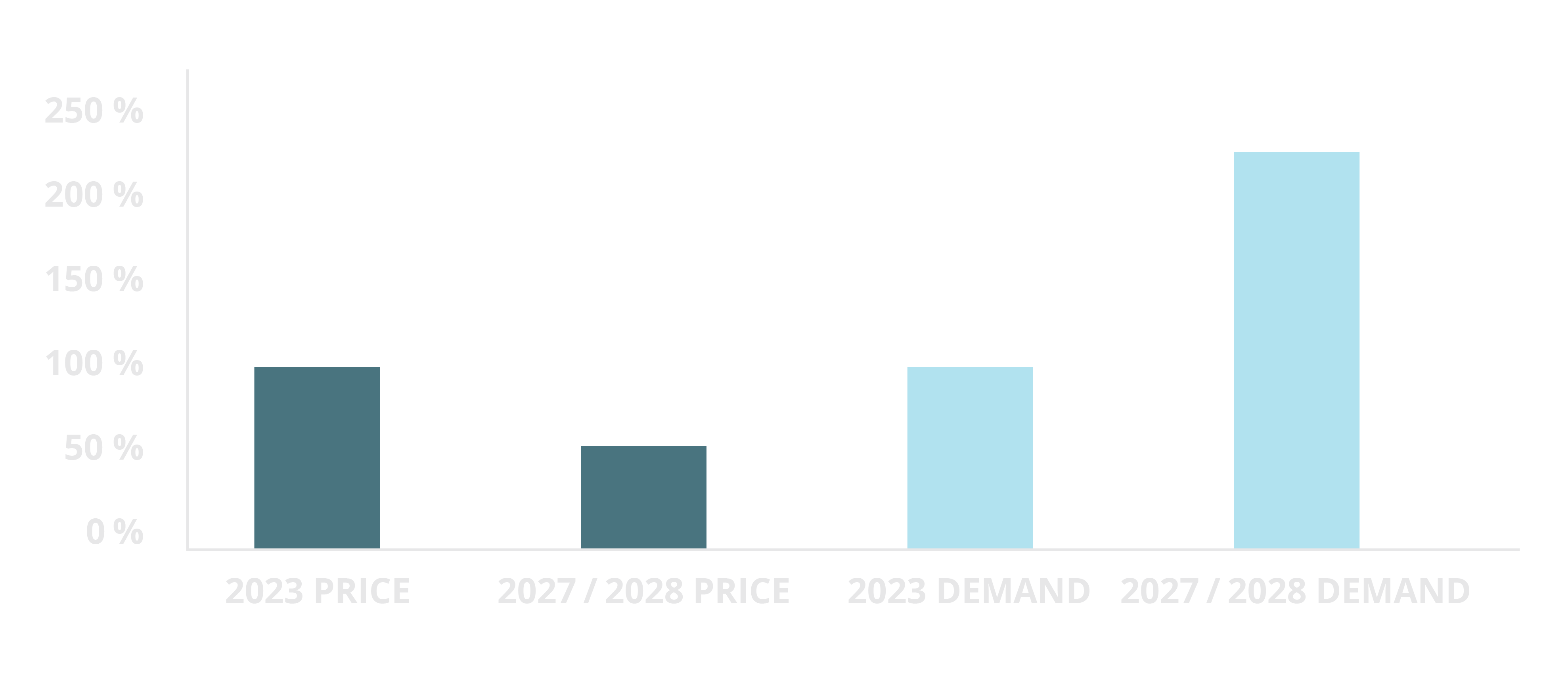

Lithium is critical for rechargeable batteries used in smartphones, laptops, and electric vehicles due to its lightweight and high energy density. As the world seeks to reduce reliance on fossil fuels and combat climate change, demand for lithium-ion batteries is surging. Consequently, lithium mining projects are expanding to meet this growing need, with a focus on sustainable practices. However, price volatility and lack of funding threatens hard rock lithium mining operations.

The Lithium Market

The energy transition is driving demand for a group of critical metals (including lithium, cobalt, nickel and copper) essential for clean energy technologies. The significant production growth in coming years to meet global and national energy transition targets will make efficient mine deployment crucial in ensuring a sustainable supply of these critical resources. CRU Group, with its decades of experience in the mining industry, is closely monitoring the global markets for these critical metals. Below, we provide an overview of the current situation and outlook for the lithium market.

What this means for miners

- DSO market stagnated due to low Lithium prices.

- Producers being penalised for off-spec concentrate shipments.

- Off-takers demanding higher grades.

- RoM variability destabilising DMS and flotation, reducing efficiency.

- Low grade feed to DMS and float not reaching target product grade.

Typical technologies and solutions for Lithium

![]()

Flotation

Typical technologies and solutions for Lithium

![]()

Milling

![]()

Flotation

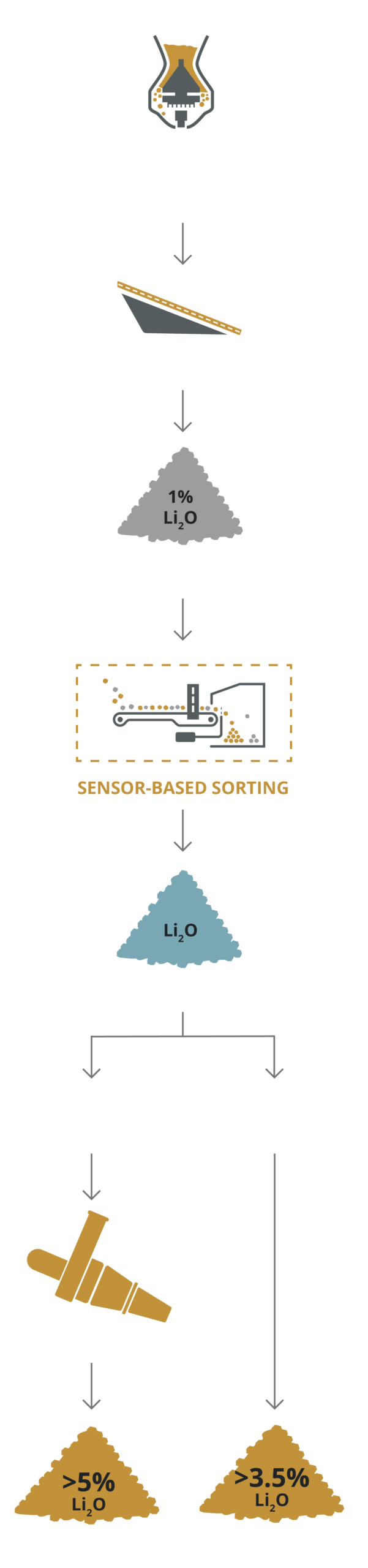

Specialty solutions for Lithium

Future proof your flowsheet and generate near-term cash flow*

Best of both worlds: Preconcentrate spodumene ore in the coarse size fraction

- Recover fine mineral with DMS to generate high-grade concentrate – at low cost, efficiently.

- Polish off-spec product.

- Utilise freed-up capacities through waste removal and increase your production.

- Minimise ore variability to avoid operational problems and associated costs at DMS and flotation level.

- Reduce OPEX through increased efficiency and decreased water and energy consumption.

- Decrease downstream equipment size.

*Time frame dependant on project requirements.

Specialty solutions for Lithium

Future proof your flowsheet and generate near-term cash flow*

Best of both worlds: Preconcentrate spodumene ore in the coarse size fraction

- Recover fine mineral with DMS to generate high-grade concentrate – at low cost, efficiently.

- Polish off-spec product.

- Utilise freed-up capacities through waste removal and increase your production.

- Minimise ore variability to avoid operational problems and associated costs at DMS and flotation level.

- Reduce OPEX through increased efficiency and decreased water and energy consumption.

- Decrease downstream equipment size.

*Time frame dependant on project requirements.

UV ore sorting

- Selectively target spodumene in the coarse size fractions (5-75mm).

- Choice to eject waste or eject product/concentrate.

- Generate a dry higher-grade product (SC3-SC5) instead of standard DSO.

XRT ore sorting

- Target waste sorting minerals to be rejected (iron/mafic/basalt).

- High capacities and minimal product loss.

- Increase DMS and flotation performance.

STARK's modular DMS

- Relocate your modular DMS between deposits.

- Use for pre-concentration to generate a higher-grade product instead of standard DSO.

- DMS optimisation and stability controls using RFID.

Select Lithium Projects We've Worked On

Kalgoorlie, Western Australia

Capabilities

+ Full-scale plant operation integration

Africa, South Africa

Capabilities

+ Economic trade-off studies

+ Expedited XRT plant deployment

Select Lithium Projects We've Worked On

Kalgoorlie, Western Australia

Capabilities

+ Full-scale plant operation integration

Africa, South Africa

Capabilities

+ Economic trade-off studies

+ Expedited XRT plant deployment

Our Lithium experts

Sonja Schadeck

TECHNO ECONOMIC ENGINEER – LITHIUM

M. Sc. BA & Eng. (Mech.)

| Germany | |

| +49 173 188 6604 | |

| sonjas@stark-resources.com |

Dian Heinrich Page

GROUP HEAD OF ADVISORY

Pr.Sci.Nat / M.Eng Geo Tech

| Germany | |

| +49 1728 170 726 | |

| dian@stark-resources.com |

Fabian Riedel

CHIEF TECHNICAL OFFICER

Dipl.-Ing. Mining Engineering

| Germany | |

| fabian@stark-resources.com |

Brady Jenkins

PRINCIPAL PROCESS ENGINEER

BSc Mineral Science / Dip. Env. Science

| Australia | |

Eleanore Luise Forner

Principal – Lithium

Pr. Eng. / B. Eng. Hons (Chem.)

| South Africa | |

| eleanore@stark-resources.com |

Our clients and partners say

Lucara's Karowe mine stands alone in the global context of large diamond recovery as the only location to recover 4 diamonds larger than 1,000 carats. As an early adaptor of sensor-based primary diamond recovery from sized run of mine material, the Stark Team over the years has been instrumental in the design, process flow, construction and commissioning of the XRT circuits. The results are a testament to incredible team work, excellent process flow, and an innovative circuit combined with a truly unique diamond deposit.

John Armstrong

Vice President Technical Services

We acquired an updated stand-alone XRT plant and within a very short space of time recovered the 91O ct D-colour Lesotho Legend diamond at Letšeng. This must surely rank as one of the best ROIs that has ever been seen!

Clifford Elphick

Chief Executive Officer

During COVID lockdown the team replaced 5 COMS XRT sorters, washing screens along with XRT building expansion. This was planned remotely with the Karowe Process and Engineering teams, and executed on the ground. At the height of the global pandemic this work was completed safely, on time and on budget, under challenging circumstances - a testament to their ability to plan and execute.

John Armstrong

Vice President Technical Services

Contact us

Looking for a customised solution for your company?

Let's get in touch.

Sonja Schadeck

M. Sc. BA & Eng. (Mech.)

TECHNO ECONOMIC ENGINEER - LITHIUM

sonjas@stark-resources.com