IMPROVE THE QUALITY OF YOUR

DSO UP TO SC6!

Add a dry beneficiation stage of Laser ore sorting

and increase your profit by up to 400% with

SMART, LASER ORE-SORTING

TECHNOLOGY IS THE SOLUTION!

By integrating this innovative technology that incorporates two lasers, your plant will be positioned to become more efficient and profitable. The Laser ore-sorting technology can detect the product Spodumene.

UNIQUE LASER ORE-SORTING

TECHNOLOGY

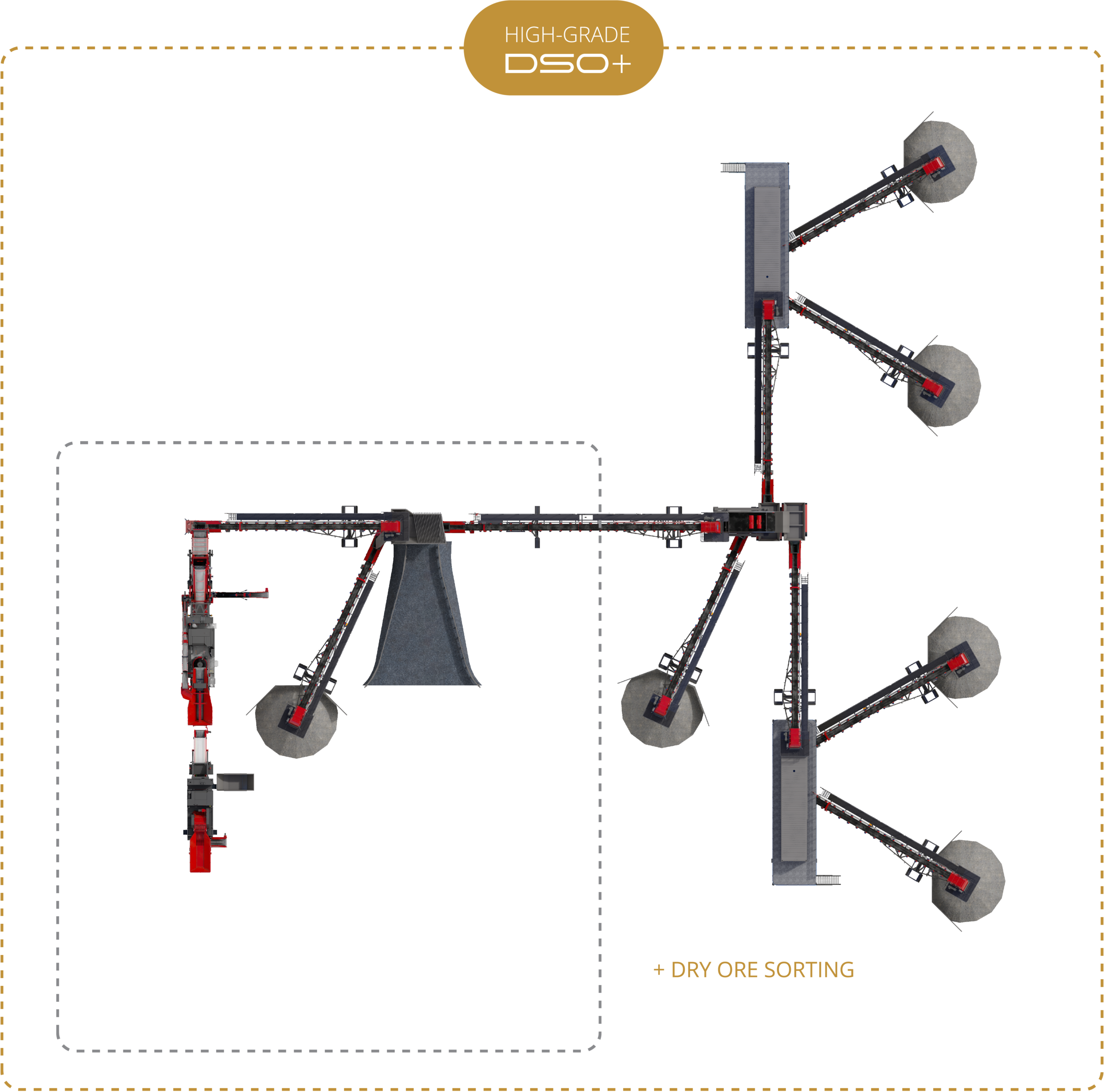

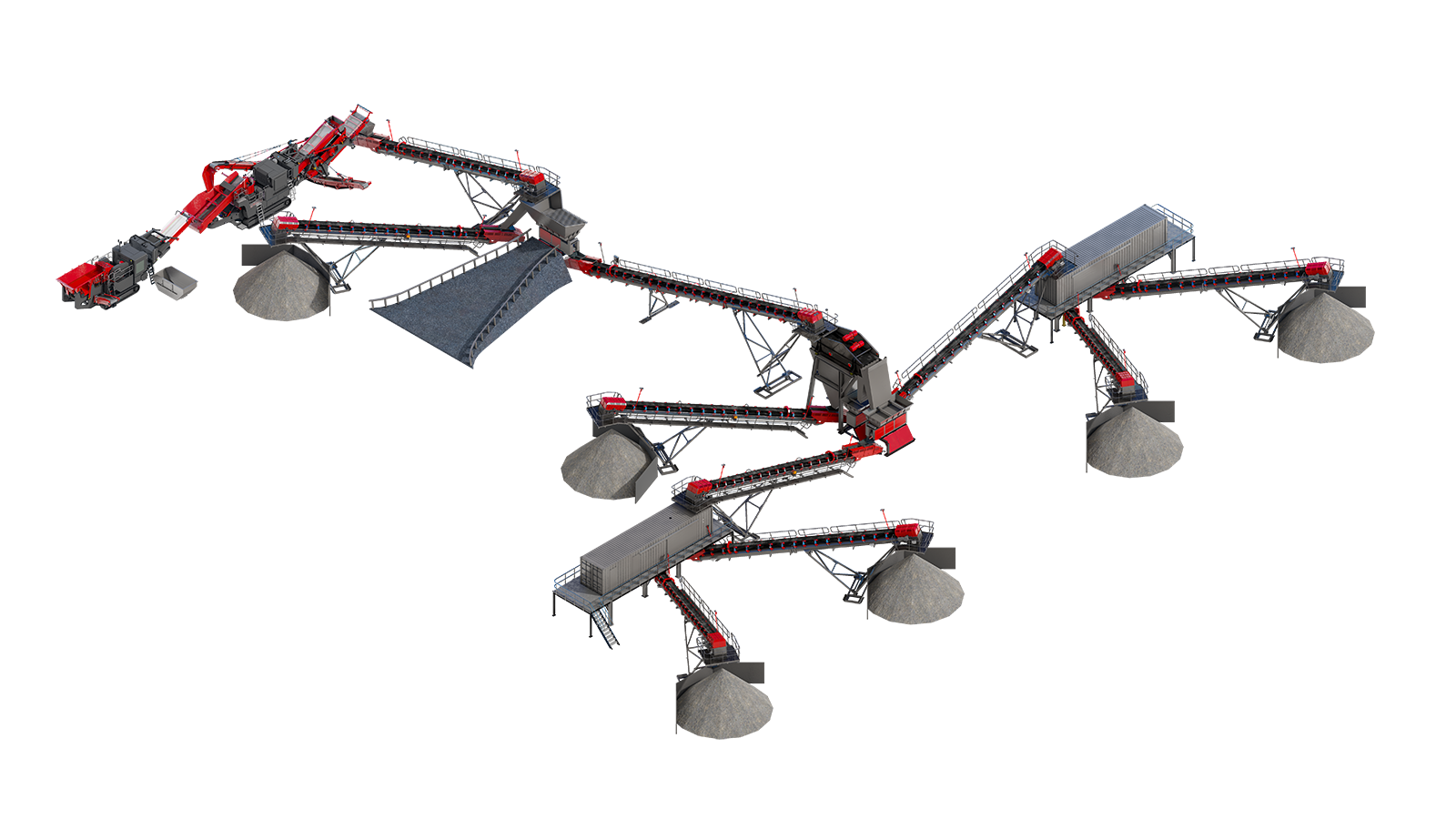

The additional beneficiation stage is designed to speed up access to saleable SC6 concentrate-grade Spodumene from complex ores. Ore sorting can identify Spodumene directly, and a high-grade DSO+ solution can be delivered on-site in a container, ready to integrate into your plant layout.

WITH HIGH GRADE DSO+

YOUR PROFITS CAN

INCREASE BY UP TO 400%

By introducing the modular plant design and Laser ore sorting, your recovery will increase from a traditional DSO yielding 1.5% Li2O to HIGH GRADE DSO+, yielding between 3% Li2O (a conservative scenario) and 6% Li2O (the best-case scenario). Your profit can increase by as much as 400%. This upgrade is dependent on the liberation size of your ore with results in as little as two years, in comparison to a traditional DSO plant.

THE CASE FOR A HIGH-GRADE DSO+ PLANT WITH LASER ORE SORTING

A prime example of holistic innovation and collaboration, STARK can build a pilot lithium plant with one additional beneficiation stage to incorporate Laser ore sorting. The objective being to increase the quality of DSO to SC6 by detecting the product, Spodumene, using 2 lasers.

Doing so positions clients to easily increase the grade of ore and trade processed ore without restrictions. With a Laser based ore-sorting solution that is delivered on site in containers and integrated into the lithium plant layout, our clients’ mineral processing operations are ready to detect Spodumene directly and run more efficiently and more profitably.

ADDITIONAL BENEFITS TO YOUR BUSINESS

GET STARTED IN 3 EASY STEPS

ORE SORTING TESTING

We conduct an Amenability Test

and determine the sorter's balance point.

PRE-ECONOMIC ASSESSMENT

We identify the profit gain that you can achieve with your deposit, develop a customised plant design, and provide a realistic timeline.

DSO + PLANT

Within 8 months you'll start high-grade

DSO production.

SCHEDULE A FREE 30 MIN CONSULTATION

Schedule a call at a convenient time and we'll talk about your project and processing plant needs. Our team looks forward to telling you more about STARK's unique DSO+ concept. After the call we will start gathering information to be able to determine your profit gain.