The misallocation of just 1% of saleable ore to the discard dump can have an enormous effect on the bottom line of your company.

Imagine if you could make smart decisions in real time and get your plant on track, increasing profitability, without having to compromise on productivity.

UNDERSTAND HOW THE MATERIAL

IN YOUR PLANT BEHAVES!

Create long-term value by taking a holistic approach and audit your mineral processing equipment. Turn as much of your product as possible into saleable ore.

STARK’S FIRST-TO-MARKET, PROPRIETARY

DMS AUDITING SOLUTION IS THE ANSWER!

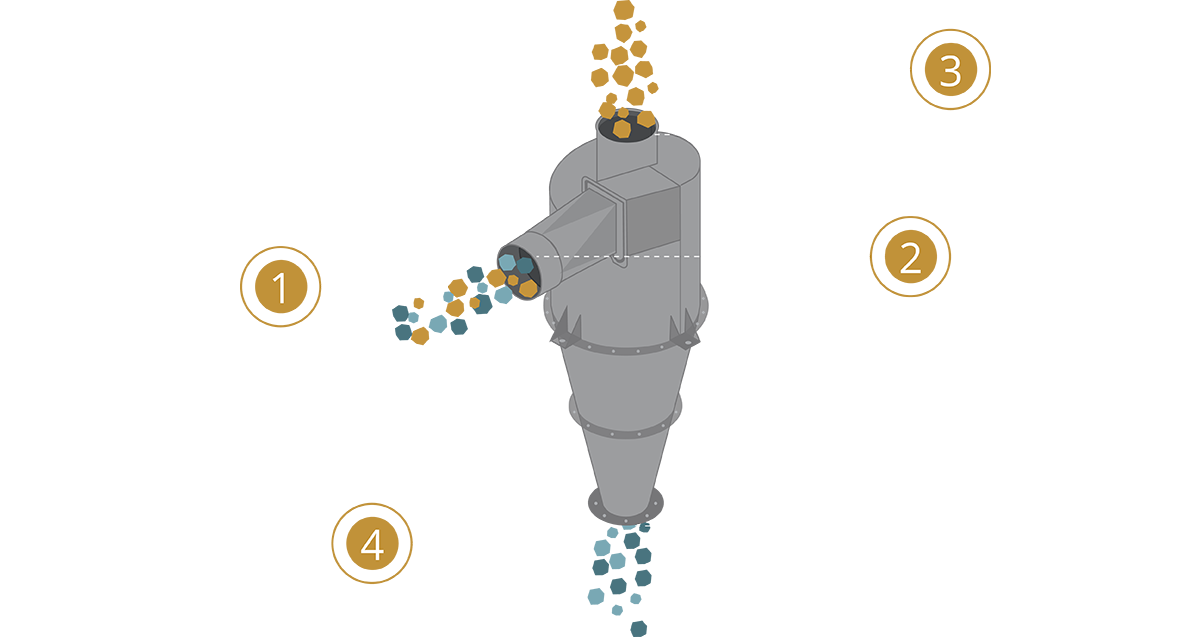

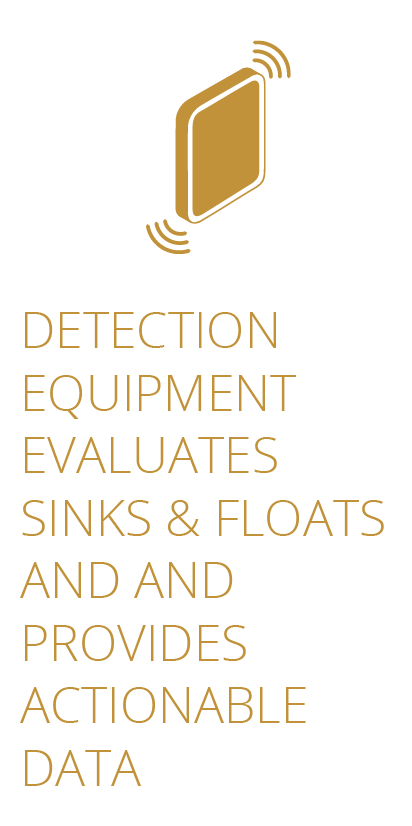

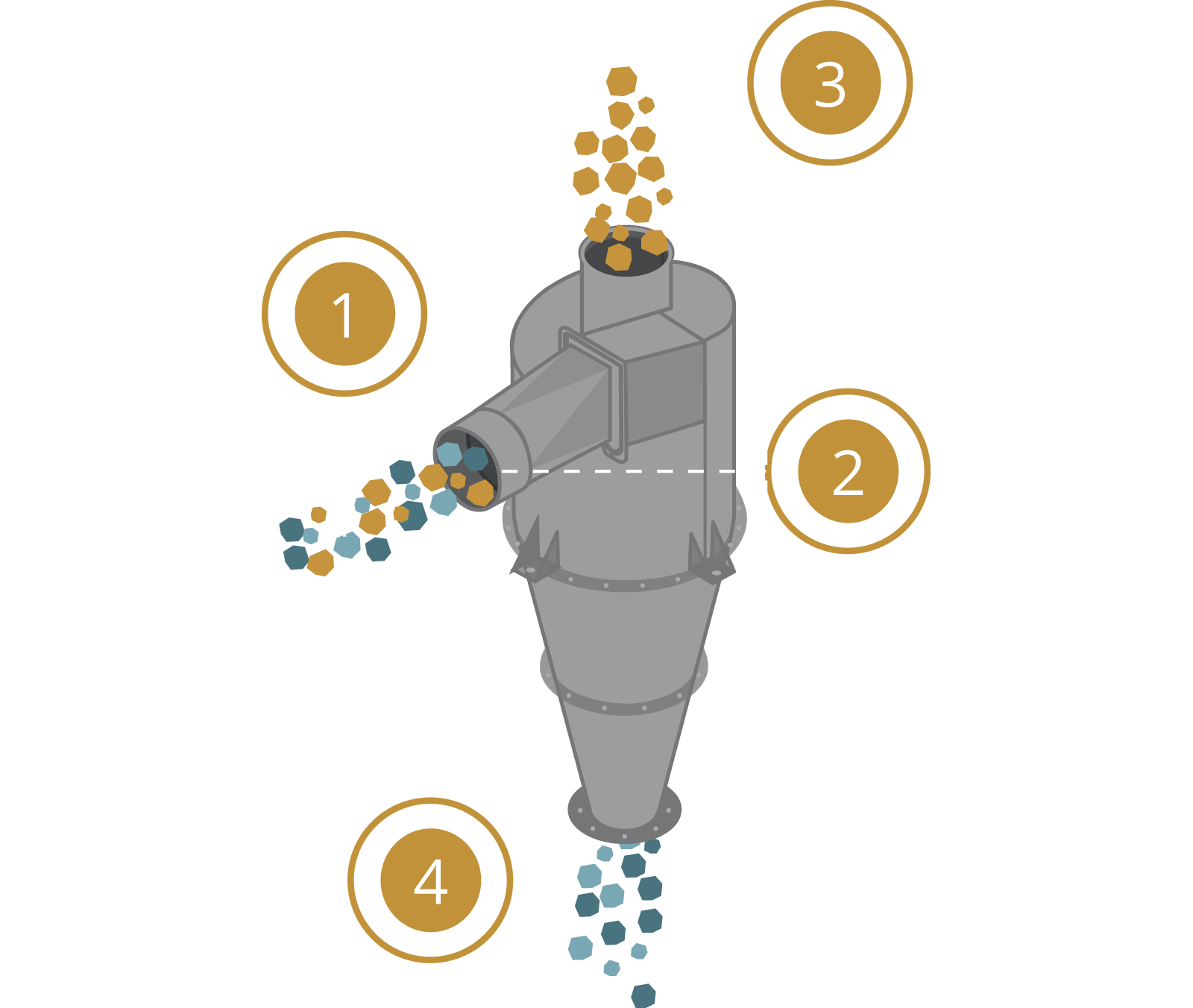

By integrating this innovative technology including tracers, detection hardware and in-house developed software into your plant, you’ll have access to accurate data and clear results that enable you to make calculated decisions and re-direct your operation where needed.

USE UNIQUE RFID TRACER TECHNOLOGY

A system that can be set up in a few weeks and provides ongoing, long-term results and benefits to your plant. Get increased visibility into the actual performance of your plant and receive valuable parameters in optimising your process. Our team of consultants will provide a real-time management service and on-going after-sale service and care, and you’ll have access to a web interface that gives you actionable data and visibility 24/7 to ensure optimal metallurgical performance.

YOU CAN SAVE UP TO $6 MILLION BY RECOVERING 1% ON 400 t/h

If a cyclone or dense-medium vessel is blocked, it’s obvious that there’s a problem. But what about when it looks to be working efficiently and is not? Saleable ore is being lost and your bottom line will suffer.

A 1% reduction in misplaced material may seem insignificant, but could amount to an annual increase in EBIT of up to $6 million.

INCREASE YOUR BOTTOM

LINE FOR THESE COMMODITIES

COAL APPLICATION STUDY

400 t / h

EXPORT COAL PRODUCTION

80 %

OEE AVAILABITY

24 h / daily

PRODUCTION RATE

$ 200

COAL EXPORT PRICE (AT Q4 ’23)

1 %

MISPLACED MATERIAL RECOVERED

Circa $ 6,000,000

SAVING IN MISPLACED MATERIAL (ANNUALLY)

ADDITIONAL BENEFITS TO YOUR BUSINESS

GET STARTED IN 3 EASY STEPS

AUDIT SYSTEM

We conduct an audit of your plant and process.

IMPLEMENT

We install a fixed installation and incorporate detection equipment to monitor efficiency curves of your plant, within a few weeks.

ONGOING MONITORING

Your material and plant are continuously monitored, and improvements are made in real-time.

SCHEDULE A FREE 30 MIN CONSULTATION

Schedule a call at a convenient time and we'll talk about your project and processing plant needs. Our team looks forward to telling you more about STARK's unique DSO+ concept. After the call we will start gathering information to be able to determine your profit gain.