The modular DMS is a distinct approach to traditional DMS. It allows for easy scalability and adaptability to varying processing requirements, making it a more sustainable and cost-effective solution in many mineral processing applications. The modular DMS is flexible and optimised for efficient operation and can include smart features to monitor real-time performance.

Watch the modular DMS in action

Enjoy the unmatched benefits of a truly modular DMS

- Effortless assembly: Flexible design, assembled from 6m and 12m container form factors, making

construction, commissioning, maintenance and operation simple and convenient. - Seamless transport: Say goodbye to abnormal load vehicles and logistical headaches. Our

modular design fits into seven standard-size shipping containers. - Rapid relocation: Need to move your DMS to a new location? No problem. The easy

disassembly feature allows for fast relocation, saving time and resources. - Improved availability: With smart design choices like optimised piping, you’ll experience fewer

blockages, easier start-up, and reduced wear on components. - Future-proofing: Upgrade your DMS to suit changing needs. Options like the FeSi makeup

circuit, Mica removal screen, multiple densifier circuit extraction points, and more provide versatility for the future. - Versatile configuration: Adapt your DMS to your needs with ease, whether you prefer a

primary or secondary DMS configuration.

Designed to increase the efficiency of your project

MINIMAL CIVIL WORK

Opt for our convenient drag-and-drop steel sump design and save on construction costs.

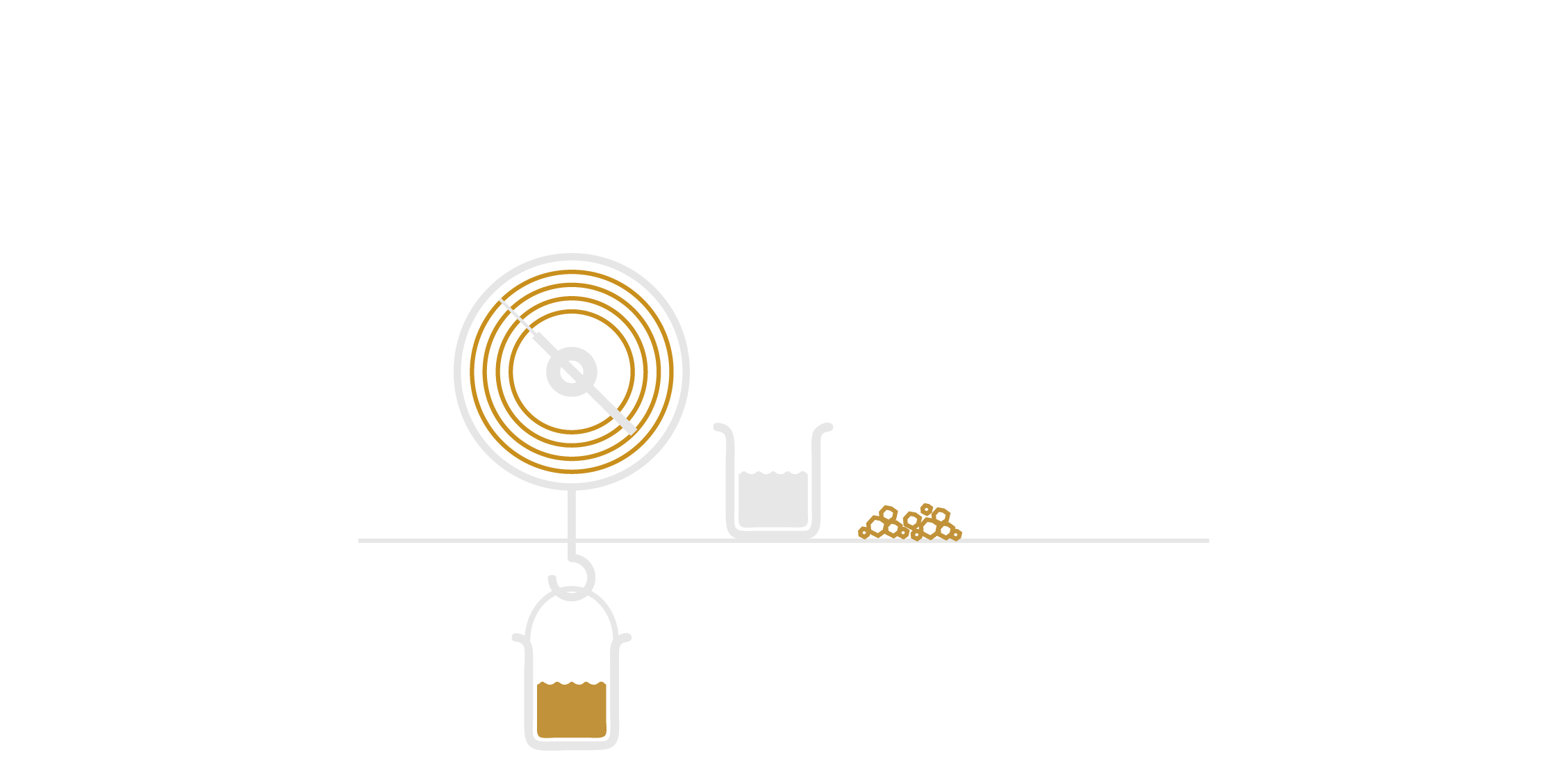

CUSTOM DENSITY CONTROL

Tailor your process with options for direct to CM tank or conventional pump suction dilution water, ensuring optimised stability or faster reaction times to positively impact production and operating expenditure.

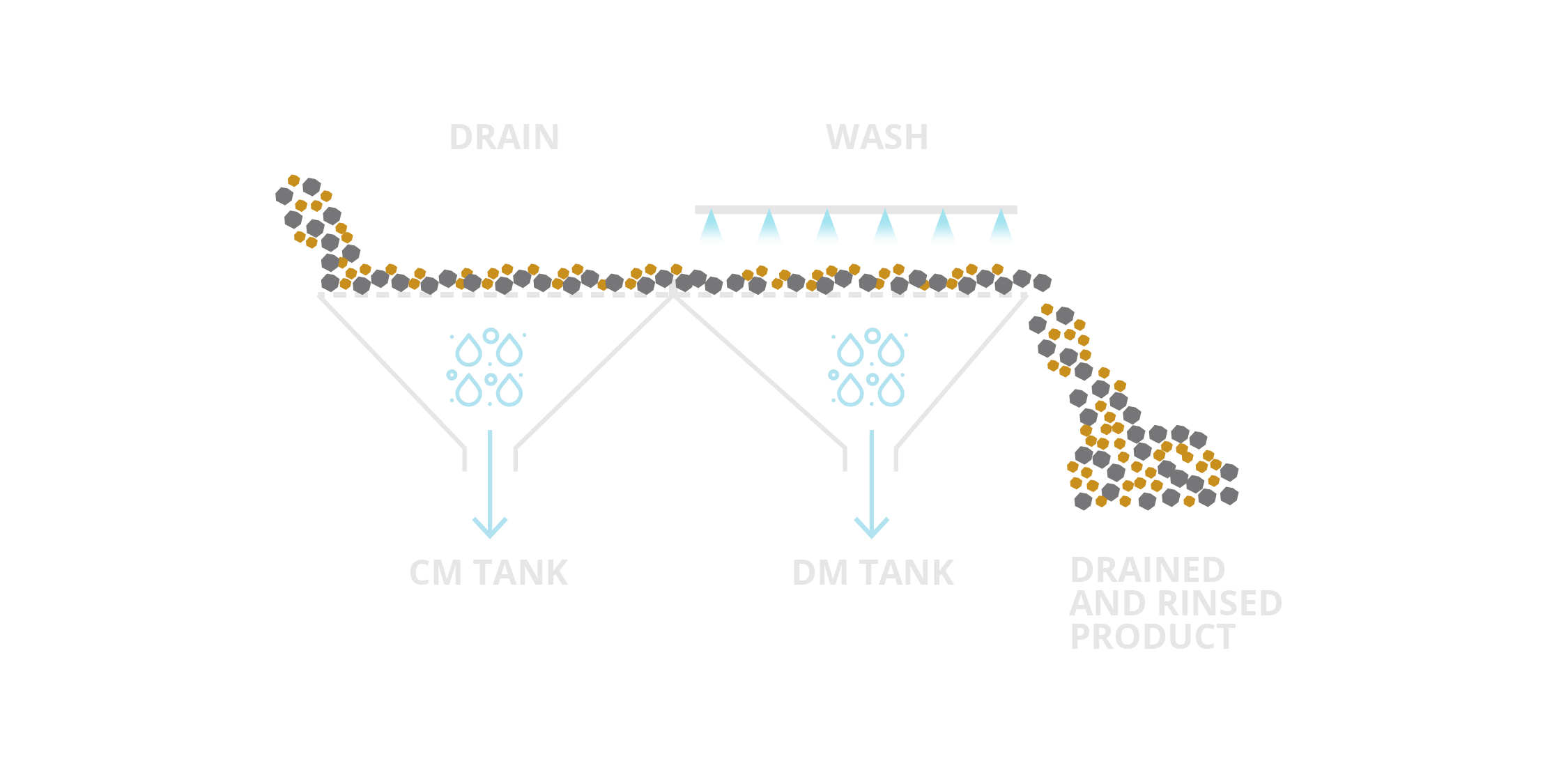

YIELD VERSATILITY

A wider screen caters to high product yields, ensuring you’ll get the most out of your operation. This design provides constant feed to the mineral processing plant in terms of composition and throughput.

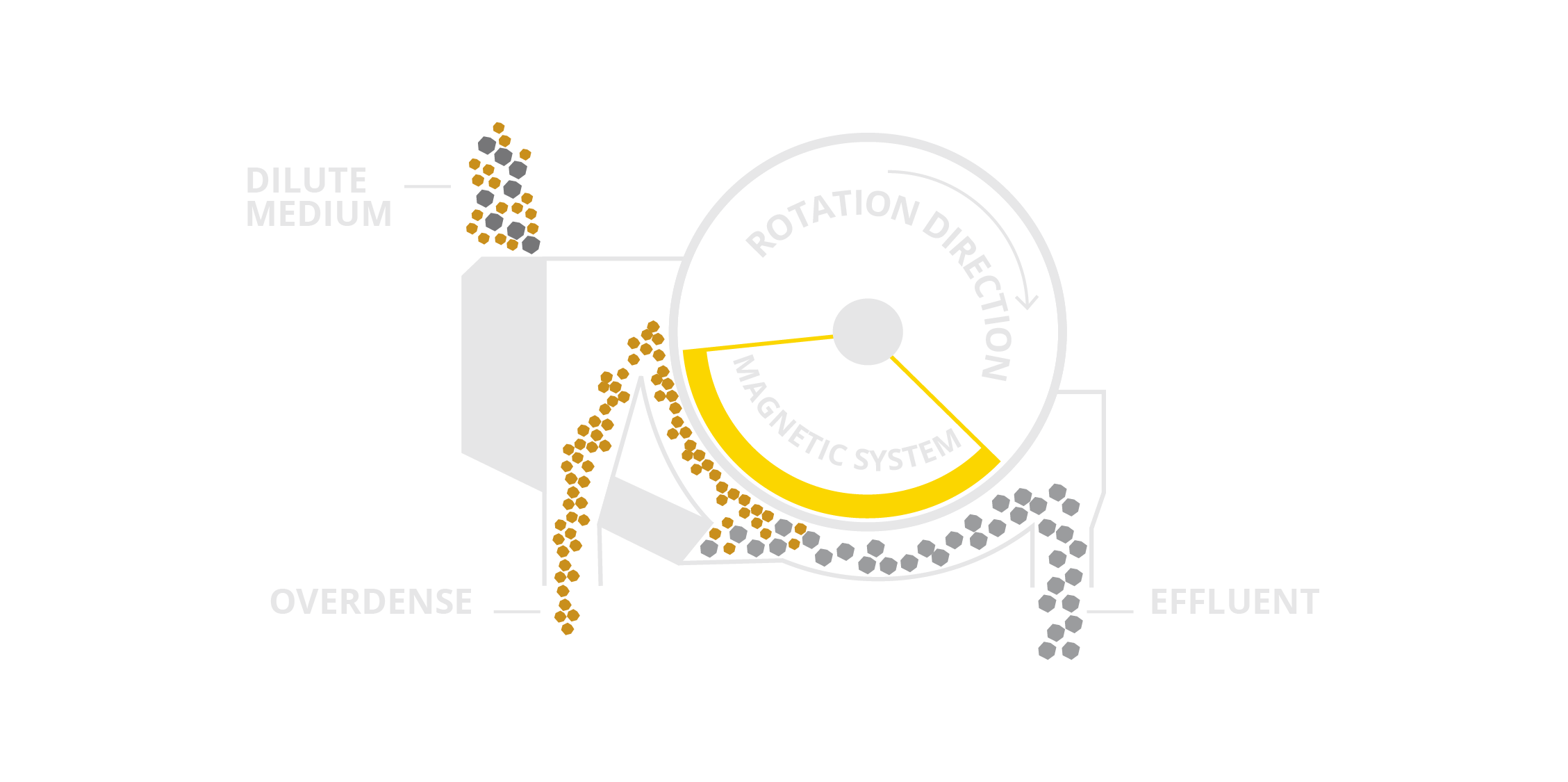

ENHANCED MEDIUM RECOVERY

A wider magnetic separator improves FeSi recovery, while a larger capacity CM tank accommodates unexpected stoppages, reducing medium losses. This matters because a 0.5% drop on a 50 tph operation would cost circa USD300,000 per annum in lost medium alone.

EFFICIENT WATER MANAGEMENT

Our optimised internal water recirculation minimises overall water circuit requirements, reducing water consumption and costs.

Take it to the next level with smart DMS

A built-in RFID tracer solution to help you maximise your recovery.

STARK’S FIRST-TO-MARKET, PROPRIETARY DMS AUDITING SOLUTION IS THE ANSWER!

By integrating this innovative technology including tracers, detection hardware and in-house developed software into your plant, you’ll have access to accurate data and clear results that enable you to make calculated decisions and re-direct your operation where needed.

USE UNIQUE RFID TRACER TECHNOLOGY

A system that can be set up in a few weeks and provides ongoing, long-term results and benefits to your plant. Get increased visibility into the actual performance of your plant and receive valuable parameters in optimising your process. Our team of consultants will provide a real-time management service and on-going after-sale service and care, and you’ll have access to a web interface that gives you actionable data and visibility 24/7 to ensure optimal metallurgical performance.

Our clients and partners say

Lucara's Karowe mine stands alone in the global context of large diamond recovery as the only location to recover 4 diamonds larger than 1,000 carats. As an early adaptor of sensor-based primary diamond recovery from sized run of mine material, the Stark Team over the years has been instrumental in the design, process flow, construction and commissioning of the XRT circuits. The results are a testament to incredible team work, excellent process flow, and an innovative circuit combined with a truly unique diamond deposit.

John Armstrong

Vice President Technical Services

Contact us

Any questions?

We are always at your service.

James Derbyshire

B.Eng (Chem)

PROJECT MANAGER: DMS & RFID

Jamesd@stark-resources.com

+27 72 124 7351